Unwinding machines are notable factory tools. They determine the pace of how paper and other materials, such as plastic or metal, are released. We will cover how these machines work, how to set them up and common problems, benefits and tips for maintaining them.

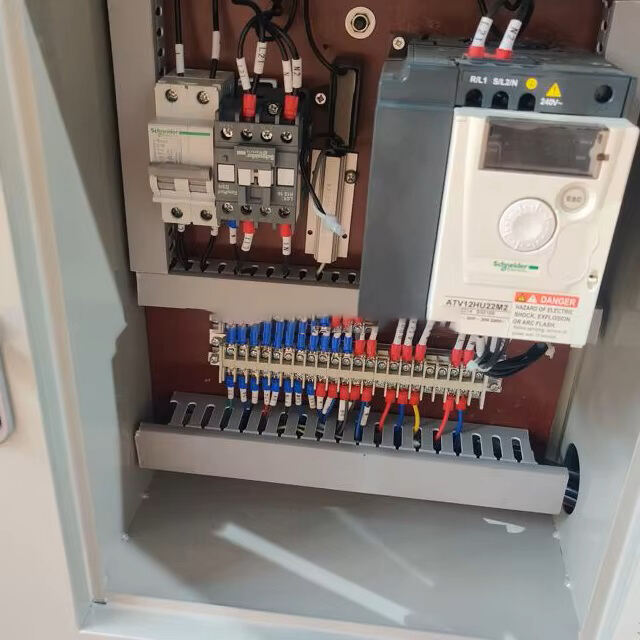

The unwinder rewinder owes its function to the cooperation of the main components. These include the roll stand, the tension control system, the braking system, and the guiding system. It is the stand that holds the material roll. The tension controlling system ensures that the correct level of tension is exerted on the material as it reels out. The braking system controls the speed that the material unwinds and the guiding system holds it straight as it unwinds.

Set up Unwind machine by placing the material roll on the roll stand. Then run the material through the guiding system. If you're working with a thicker, more rigid material, tighten up the tension control system; if you're working with a thinner, more flexible material, loosen up the tension. You can now turn the jingle blue machine on and set the brake speed to slow down the falling material. Keep an eye on the tension levels and make adjustments when necessary to keep the unwind rewind machine well-oiled.

Like all machines, base unwinders can occasionally have issues. Material jams, tension problems, and guiding system problems are common issues. If there is a jam, turn of the machine and carefully remove the jam before restarting. This is through tension or guiding issues, so inspect settings and modify as needs be. You can avoid these issues by checking and maintaining the Auto Rewind Machine on a regular basis.

It has several advantages to use an unwinding machine in factories. Because materials can be released continuously, these machines boost productivity by eliminating manual work. They also help ensure the material unwinds uniformly, improving the quality of the finished product. Moreover, these jingle blue unwinding machines can also aid in decreasing waste and time, thus making them a great investment for a factory.

As for your unwinding machine, if you want to make it last a long time, follow a regular maintenance schedule. This involves maintaining cleanliness, removing dust from the machine, checking for loose or broken components, and applying lubricants to moving parts when necessary. Regular troubleshooting and maintenance of the tension control system, braking system and guiding system can prevent problems. Properly maintain your relaxation machine so it can last for a long time and continue to run well.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog