Flexopress is the new generation for designing p Flexo Printing Machine packaging in various materials such as plastic and paper. Instead of banding a cylinder with one long plate around its circumference, the printer uses flexible plates. These plates are what carry the ink to make the packaging, so these can produce stunningly detailed designs. Get it quickly and efficiently for printing high-quality prints. It's not only amazing — but it's also magic

FLEXO PRESS: SAVING TIME AND MONEY FOR PACKAGING COMPANIES: One of the best advantages of using the flex press is that it saves both time and money for packaging companies. Built-in top-of-the-line technology makes our printer quick and easy to set up, with design changes a simple process. This makes it possible for packaging companies to create numerous designs in a single day, thus increasing their pace and efficiency.

Flexo printing offers another great advantage of using less ink than other methods of printing. Once combined, the printer spreads the ink evenly over the outline of the Die Cutting Machine design, allowing for a clean and clear image while also saving money on ink costs. Companies can also help reduce waste by using less ink, creating a greener alternative

This guide discusses multiple benefits of the flex press for package printing. A tremendous advantage of that is how flexible this printer is. It can print on various materials, like paper, plastic, cardboard, and even metal! That means companies can produce diverse packaging for all kinds of products on the same printer.

So, flex graphic printing also has another great aspect: There are nearly no limits regarding even your designs! Flexo printing can indeed produce extremely complex and detailed designs which enable your Inline Flexo Printing Machine product to be distinguished in the shelves. With retail in this competitive age, it is so vital. When customers walk into a store, they must have picked up the product considering how appealing the pack is. Colorful and eye-catching packaging is crucial to your product being considered when the consumer is in the purchasing phase.

Flexo press technology also guarantees consistency and accuracy in every print. Using the design, the printer creates a special plate where the plate is created using digital imaging technology. The design is copied onto that plate. This process has the same design as every print with no variations.

We strive to offer the best packaging products to our customers at Jingle Blue. This is the reasoning behind our choice of flex press technology to bring the product packaging in the most colorful and detailed designs. The thing that set us apart from the competition was our commitment to quality and customer satisfaction. Happy customers are good to us, and when our customers love their packaging, we know that also means success for their products in the marketplace.

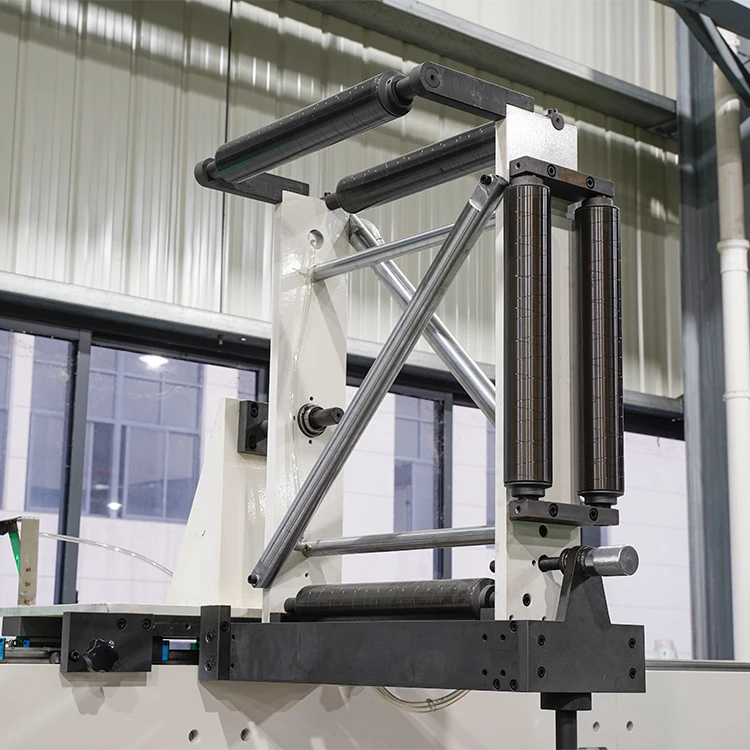

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog