Ever wondered how your favorite tape, labels, or stickers are made? Essentially everything starts with this unwind rewind machine. You rotary die cutter might be wondering what an unwind rewind machine is all about and how does it matter? For example, an unwind rewind machine takes in a spool of tape, then rewinds it on a different spool.

This is done because the machine minimizes waste of these materials by cutting them a snug fit. By cutting to the exact size paper slitter needed, instead of the nearest standard width, the machine conserves precious resources (like tape, labels, or stickers). It also means less time spent in the manual cut, which can be tedious and time-consuming.

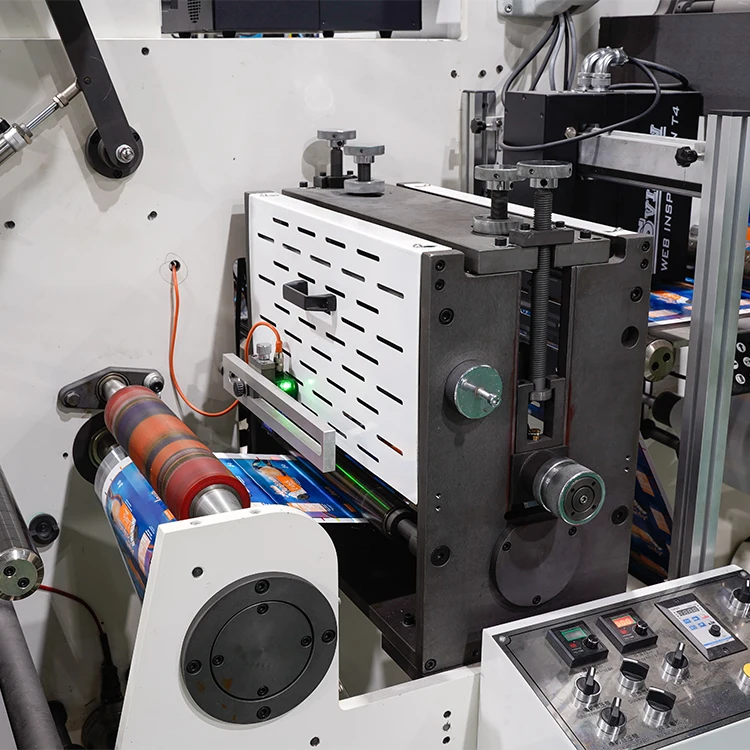

To really get a sense of how an unwind rewind machine works, just imagine it as a printer. But rather than printing ink on paper, it film prints tape on a fresh roll. It starts with a main spool that stores the raw material. The machine pulls the material off this reel. Next, the material gets passed through a series of large rollers that keep it straight. These rollers are critical to ensuring that the material stays straight and feeds smoothly through the machine.

One method for conserving time and making the tape, label, and sticker making process much smoother is the unwind rewind device. People often waste time and resources hand cutting and packaging materials.

Jingle Blue is the unwind rewind machine explained perfectly, among several others, that'll ladder up to help you better condition your tapes. October 2023: Jingle Blue – the name behind quality unwind rewind machine Ideal for a whole range of manufacturing and industrial tasks, these machines are capable of doing so many things. They are all built with high quality in mind, and they are strong, robust, and designed to last a long time. Our machines all have very effective and user-friendly control panels which allows access to all critical functions and settings easily.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog