Jingle Blue Rotary Die Cutter Machine is an efficient tool used for cutting high volumes of materials in quick time. It has a rotating blade which makes it perfect for cutting various materials such as fabric or paper. This machine cuts multiple pieces at once, an efficient way to produce many products at once. Since it is capable of processing multiple pieces at once, it allows companies to save time and be more productive. That has the advantage of potentially cutting through more materials in a shorter time frame, and it also minimizes the risk of error.

One of the most prominent features of the rotary die cutter is that it is highly efficient. This means it can draw very fine shapes or patterns, without error. It works with a wide range of materials ranging from paper and plastic to foam, fabric and even metal. You always know exactly what it’s going to do, every time you cut something with it. This accuracy is crucial for companies, guaranteeing that all the manufactured products are similar and confirm to the same quality requirements.

Once there was no rotary die cutter, cutting materials became a long and exhaustive task. They were forced to waste countless hours and man-hours cutting materials by hand or ineffective tools. But this machine has made cutting much simpler and faster. It is time that would have been wasted cutting and trimming material. Compared to the paper die cutting machine, the only thing you need to do is to set the required settings on the machine and when it starts the cutting work, it does it precisely every time it runs. This enables the worker to focus on other tasks while the machine manages the cutting process.

A great thing about the rotary die cutter is that it is very adjustable. Hence, the machine can be modified or adjusted to cut different shapes or dimensions based on the customers' requirements. The rotary die cutter can be adapted to the specifications that a particular business may need, whether that be a design or a size. It can also be designed for use with various types of materials. This versatility makes the rotary die cutter an essential tool for businesses with diverse manufacturing requirements.

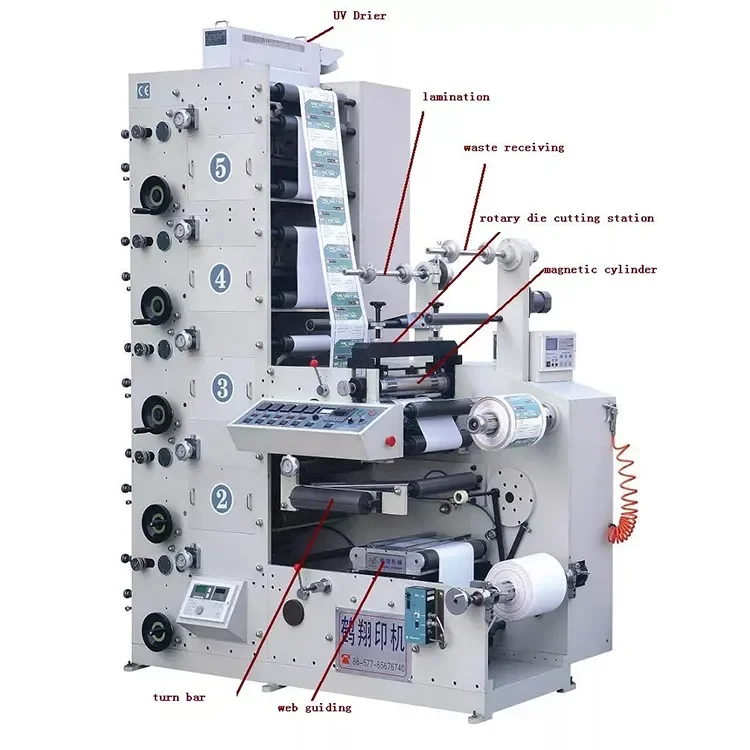

So what are the parts of a jingle blue rotary die cutter and how do they each perform their task in unison? The key part is the cutting plate which comes on the roller. The paper cutting machinery contains sharp blades that are meant to slice through not only paper and cardboard but also through other tougher materials. The roller is also critical to the process; it helps stabilize the material as it cut, ensuring accurate cuts.

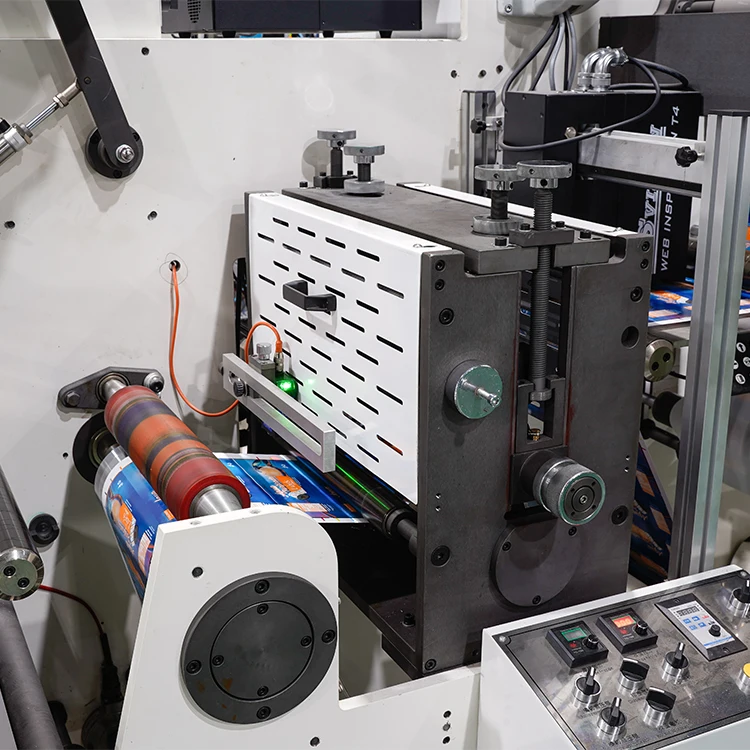

The machine also has sensors that can be monitored to ensure that cutting is proceeding as planned. The advantages of rotary die cutters also increase with new versions that can cut and stack materials at the same time. It's a new innovation that revolutionizes the manufacturing process and indicates Jingle Blue's intent to always produce machines that provide versatile and reliable workmanship to their clients.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog