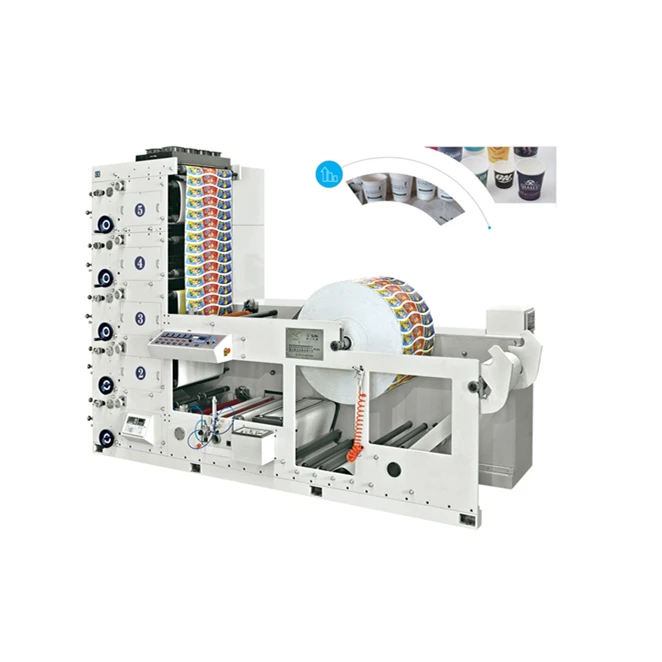

Cereal box or candy wrapper are printed with a Flexographic press, along with flexographic printing machine. The flexographic press is a tidy printing press that rolls flexible rubber plates in paint to cover various materials. These can be paper, plastic, or even metal. This type of printing is very effective, producing high-quality prints of all types that we encounter in our daily lives especially packages and labels.

As the demand for high quality printing for their products increases, so does the popularity of flexographic presses, also the slitting machine by Jingle blue. Due to their productive nature and are reliable, they are able to print out a large number of prints without wasting time or any resources. Printing machine has become a lot better through the years. This has since sped up the printing process for them to create many copies and helps businesses cut costs over time. So if you are printing food packaging or labels for drinks, flexographic presses are a suitable choice for fast and extremely precise printing that can meet the requirements of a wide variety of different industries.

There are so many choices when it comes to printing, as well as Jingle blue's product like Rotary Die Cutting Machine. A flexographic press offers some distinct advantages over other printing methods. Jingle Blue’s flexographic press, for instance, is capable of printing on a number of materials, allowing them to take on a wide variety of projects. It does print faster than competing machines, which makes it a very efficient option, too. It is also able to apply water-based inks that are less harmful than other types of inks that can be toxic. This makes it an excellent option for companies looking to produce sustainable packaging.

The Amazing Flexographic Press — Revolutionizing Industrial Printing

This incredibly significant printing approach permits printing organizations to create various high-grade prints in a brief period without settling on quality, same with the Semi Rotary Die Cutting Machine created by Jingle blue. We are aggressively taking printing to the next level with Jingle Blue. With our flexographic printing technology, we help to customize the packaging and labels and clear the products as per the requirement of our clients. This allows businesses to design unique and appealing products that make more of an impact on shelves.

Flexographic Press There are many advantages of using a flexographic press. This technology has revolutionized the printing business and is currently utilized in packaging, labels, as well as dishes, among other things. Another of flexo printing's major advantages for printing companies, is the fact that flexo presses work with a wide variety of materials including paper, foil, and plastic. This gives heavy print business the flexibility and lower cost to create better prints, which is ideal for packaging and labeling companies that need to produce large quantities of few products.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog