Slitting Machine Lines Slitting Machine Lines are used to cut to length material. These flex printer devices are found in all manner of workplaces where they produce the products we use every day. So how are slitting machine lines is making them indispensable? A slitting machine line cuts a large roll of material into narrower rolls, or into several narrow rolls at the same time. The machine is programmable to allow the width of the strips to be adjusted according to size requirements of different products. This technology allows cutting to be quicker, easier, and more cost-efficient for companies.

Machine slitting lines have revolutionized the way things are manufactured in most industries. They rotary die cutter helping companies like yours develop and deliver superior products faster than ever. Slitting machine lines will allow businesses to produce more items in less time, so they can keep up with what customers demand, and continue to compete for lower prices.

Businesses will have unique material cutting needs, and not every blade will support every manual type. Which is why slitting machine lines can be customized to suit the individual requirements of businesses. For instance, a company that produces packaging might require something called a slitting machine line that cuts paper into thin strips, while a company that rotary die cutting machine produces metal parts might need a machine that cuts metal sheets into exact sizes.

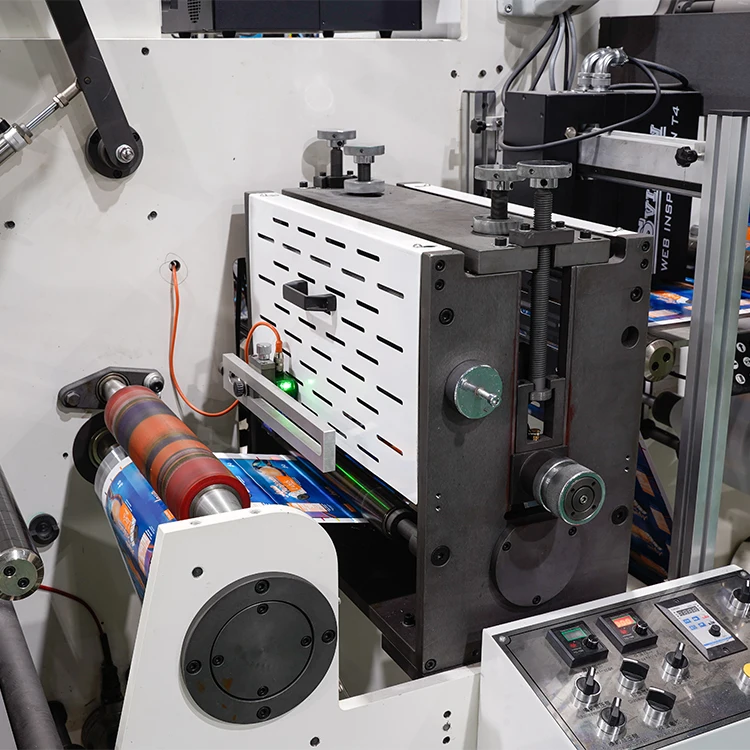

Slitting machine lines are a tangle of moving parts working together to sever materials into strips. The paper die cutting machine blade is the definitive part and it shifts back and forth for the cuts. The machine also contains sensors that control how fast and how wide the cuts are, ensuring that the strips are the proper size and shape.

Slitting machine lines play a critical role in manufacturing. They flex graphic printer assist companies in coming up with the materials that go into the production of products ranging from food packaging to car parts. ‘Without slitting machine lines, it would be difficult if not impossible for businesses to create materials accurately and quickly, leading to delays and increased costs.’

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

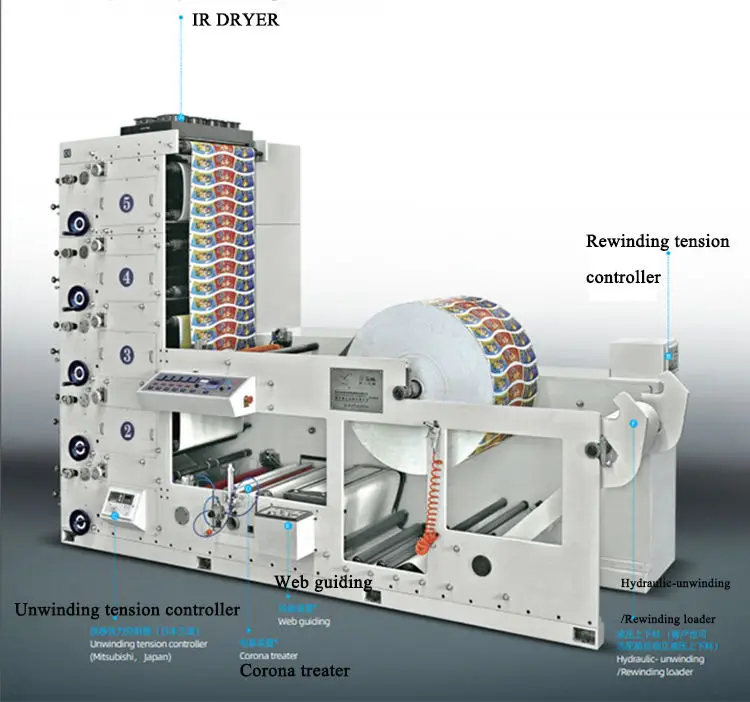

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog