So, Stickers are a great way to decorate your crafts or to make your project look appealing. You can use them for your notebooks, gifts, or just for fun. We, Jingle Blue love stickers and want to spread the sticker making joy to you!

Sticker printing is the process of printing designs to sticker paper using a printer. You can either sketch your designs manually or create them on a computer. Download the prepared art and print out the designs on sticker paper with your home printer. Cut Out the Stickers After printing, it’s time to cut out the stickers! You can either use scissors or a cutting machine Cutting machines to cut stickers, the jingle blue flexo printing press quickly and neatly, make the stickers very professional.

Making your stickers is a fun way to customize your crafts and gifts. You can create stickers according to your style using different sizes, colors, and images. For printing custom stickers, use stickers paper and set up the best print setting on your printer. When you print it out, use scissors or a flexo press printing to cut them out. And remember to share your cool stickers with friends and family!

You can trim stickers into nice looking pieces. Simply jingle blue flexo printing machine with scissors is the old-fashioned and low-cost option. However, if you need more even cuts, you may prefer a cutting machine. Cutting machines are quick cutters that allow quick cutting stickers, it is primarily used for big sticker projects. They, too, have different settings to help you customize your cuts.

A few tips to making great sticker prints. To prevent smudges or blurry prints, use the correct printer settings for sticker paper. To achieve bright and sharp stickers, always use good quality images. If you’re using a cutting machine, make sure to test it out on a small piece of paper before cutting out all of your stickers. Store your finished flexographic printing press in a cool, dry place so they don’t peel or fade.

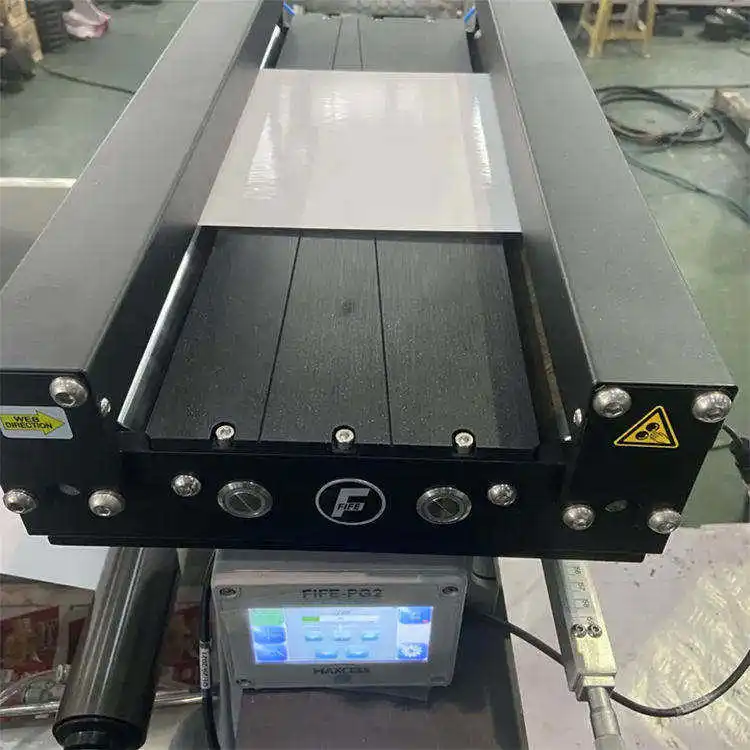

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog