The slitting line machine is a unique machine that is designed to slash large pieces of metal materials into smaller bits. It is vital in many factories, among them car, airplane and toy manufacturers. In this lesson, we will discover the jingle blue slitting equipment and how it is used to make things we use every day.

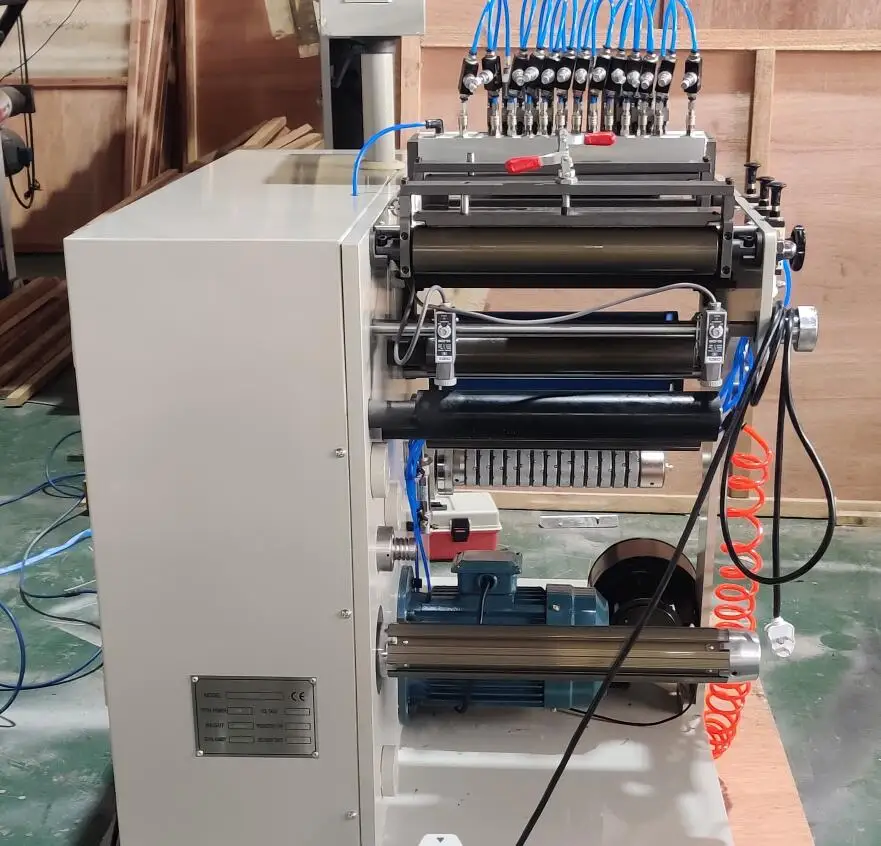

A slitting line machine is an enormous machine that is constructed from several components. The blades are sharp and cut through metal sheets very efficiently. The machine also includes rollers that aid in moving the metal sheets through the cutting process. This technology now allows quicker and easier cutting of metal into smaller parts. These broken pieces can be turned into other products.

A slitting line machine is used to save time and money. When it is done by hand, that process can take a long time and might not be very precise. The machine can do the job right and fast. This enables companies to produce more products in less time, and that may allow them to make money.

Operating a slitting line machine requires particular training and safety precautions. Wear gloves and even goggles if you have them while working with the machine. Before you use the machine, ensure that it is correctly installed and follow the instructions given in the manual. But if workers use the machine safely, they stay out of harm’s way and things hum along.

When deciding on a slitting line machine, one must keep in mind its critical features. Look for powerful blades that cut through metal cleanly, strong rollers that last and a control system that is easy to use. Choosing jingle blue paper slitting machine with these features can help companies produce high-quality products.

Slitting line machines probably will become even better in the future. So there’s the potential for machines that cut metal even faster or machines that can be controlled by computers from across the country. These new concepts of jingle blue paper roll slitting machine could potentially help companies to produce more of a product quickly, and make it possible for them to remain competitive in the new world of manufacturing.

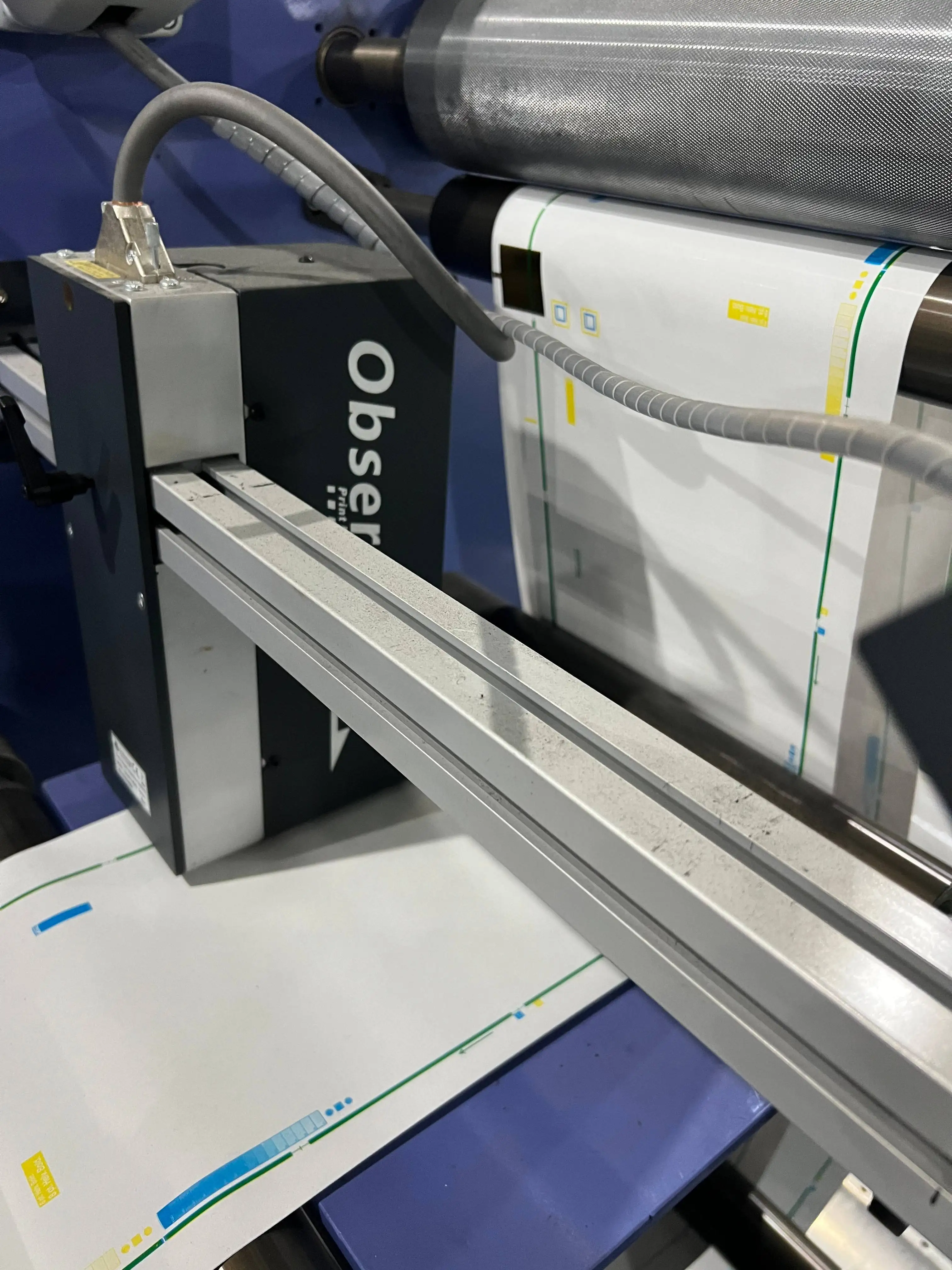

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog