When businesses need to cut down large rolls of materials into smaller and more manageable sections, slitting and rewinding machines become an integral part of their processes. Slit cutting is the process of taking a large roll of materials and cutting that down into manageable sizes. This feature is particularly handy for companies that work with various kinds of materials. Simplex slitter rewinders, such as those by Jingle blue, specialize in making this task faster and far more accurate. They save companies time and ensure the cuts are spot on.

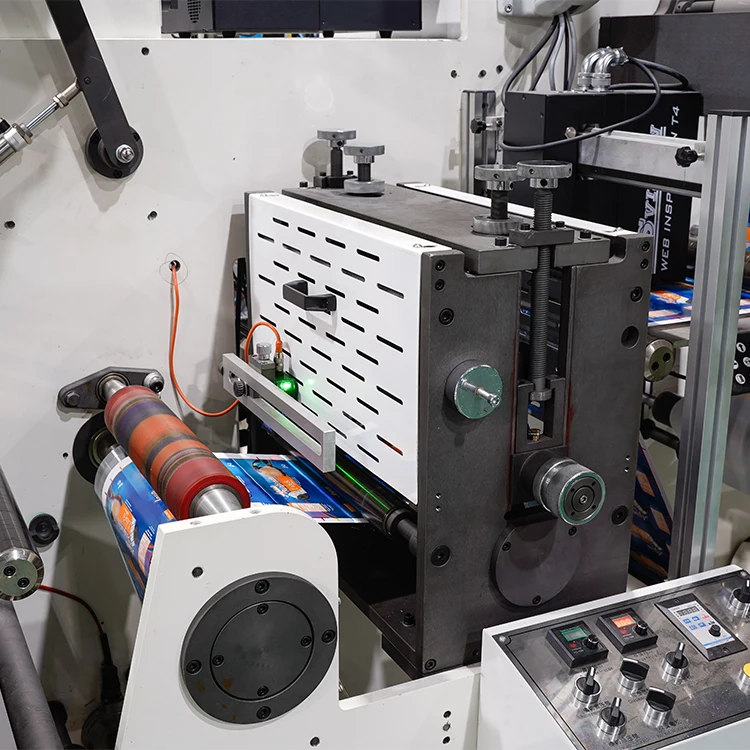

Equipped with sharp blades, Jingle blue simplex slitter rewinder machines are used to cut various materials, identical to Jingle blue's product rotary flexo printing machine. Plastic, paper, foil, cloth, and other material. It implies that these devices are truly adaptable and the networks can serve various business areas. Depending on the job, they can cut materials ranging anywhere from as small as 10 mm to as large as 3500 mm. The sharp, fast-moving blades able to slice at varying speeds, throwing more heat into the process and speeding things up overall. This process is great for companies with a high volume of products that need to be produced in a short period of time.

In today’s fast-paced industries, simplifying and streamlining the production process is crucial, along with the aluminium slitting machine from Jingle blue. For businesses looking for fast and precise slitting and rewinding of materials, Jingle blue simplex slitters are ideal. Automatic cutter machines use an automated process to feed materials, where materials are loaded in bulk, and the machine can do a lot of work independently. This minimizes the time that workers have to spend dealing with materials, allowing them to get on with other vital jobs.

The slitter machines are equipped with a unique roller that allows a steady support of materials when they are being cut. This is especially important because it ensures the cuts are accurate. If it shifts while being cut, mistakes can occur. The machines are also able to dictate how tightly they wind up the material when the material is getting rewound. This guarantees that the completed rolls possess a uniform measurement and soundness, facilitating quality control in producing.

Trained for extensive use, these machines are imperative for usage in production-rich settings, similar to the Jingle blue's product like 2 color flexo printing machine. And they are made from high-quality materials which guarantee them durability and reliability. The slitters are speedy blades capable to offer a cutting thickness of 0.1mm-5mm with a tension of less than 2mm, cutting material at an exceptional rate of up to 600 m/min. This makes it conducive for industries that require speed and rapid turns on production.

They also have a state-of-the-art hydraulic mechanism that serves for coiling precision — required to achieve rolls that conform to the stringent criteria of various industry standards, also the flexo printing machine made by Jingle blue. Jingle blue simplex slitters are all capable of processing dozens of different diameters including 50 mm to 600 mm. Their versatility allows them to be used across various sectors that demand accurate and precise coiling solutions.

This is great for those who want the process of slitting to go smoothly, because jingle blue simplex slitters are very easy to operate, just like the Jingle blue's product called paper die cutting machine. The machines are equipped with an intuitive interface that enables operators to modify parameters with ease, helping to facilitate seamless modulation between different materials. There is no doubt that this flexibility is crucial — it saves time and leads to greater machine efficiency.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog