Rewind slitters are really cool machines that factories use to cut shit like paper, plastic, and other things into smaller pieces. They are these magic-machinery things that make cutting easier and faster. Read on to learn more about these remarkable machines and how they make the world a better place in factories!

Benefits of Rewind Slitters: The rewind slitter offers many benefits that enable businesses to save time and money. A great advantage is that they can cut quickly and accurately. Which is less waste and less precise cuts. That’s excellent for any company that must produce lots of things and wish them to be flawless every time. With a rewind slitter, a company can also tailor the width and length of the cuts, super useful for making different-sized products.

A rewind slitter is a device that helps companies cut things quicker and get more work done in very little time. jingle blue slitter rewinder machine allows them to make more products and to rush to meet deadlines, which is critical in fast-serving factories. Rewind slitters are also cost effective by minimizing waste and errors. That enables companies to be more efficient and competitive.

Of course there are all sorts of rewind slitters, designed for certain types of cutting jobs. Others are small and can be easily carried, ideal for making cuts in particularly tricky spaces. Larger, jingle blue slitter and rewinder can be used that can handle the toughest stock. Based on the materials they use and their size lines, companies can select the perfect rewind slitter.

Like any machine, rewind slitters require maintenance to keep them in good condition. In fact, companies should be cleaning and inspecting their rewind slitters regularly to ensure they’re not causing damage that will reduce their usable life span. By maintaining their jingle blue label slitter rewinder well, businesses can avoid expensive repairs and keep their production schedules on track.

The reason all of these companies are able to get the most of their rewind slitters is because they took the time to learn how to use their rewind slitter properly. By the instructions, they employ the jingle blue label rewinder machine for the neat and vibrational cutting. This involves setting it for different materials, keeping the blade sharp, and generally monitoring the cutting so it’s perfect every single time. There are good quality products that people will love but companies have to know how to make them.

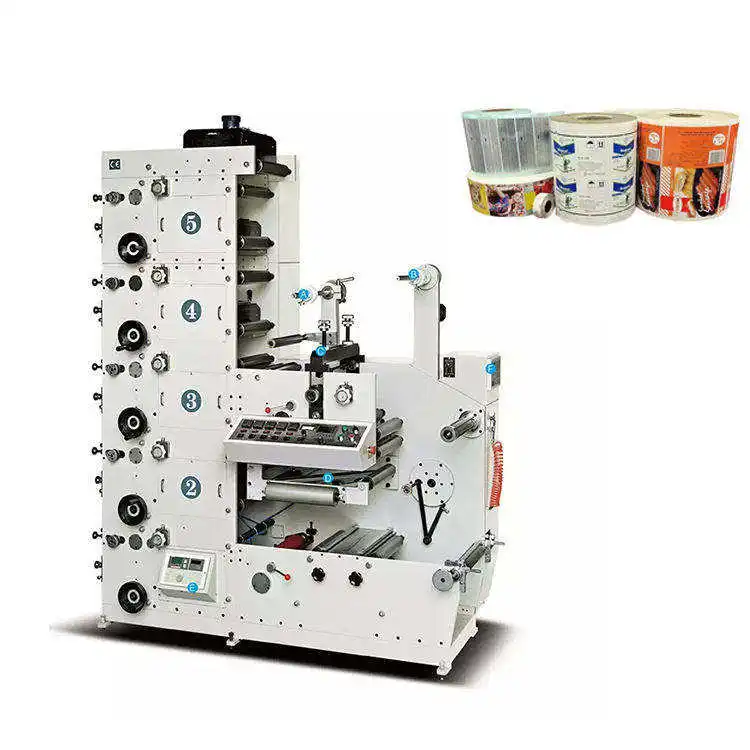

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog