Flexo machines are so neat: We use them to create a lot of fun stuff that we see and use every day, including stickers, labels, and packaging for our favorite snacks. These devices also play a crucial role in producing visually appealing and functional outputs. The best known of these machines is made under the brand name Jingle Blue. In this article, The Ultimate Guide to Flexographic Machine Operation, we discuss the working principles of these machines and a few tips on operating jingle blue flexographic printing machine to achieve the best outcomes possible.

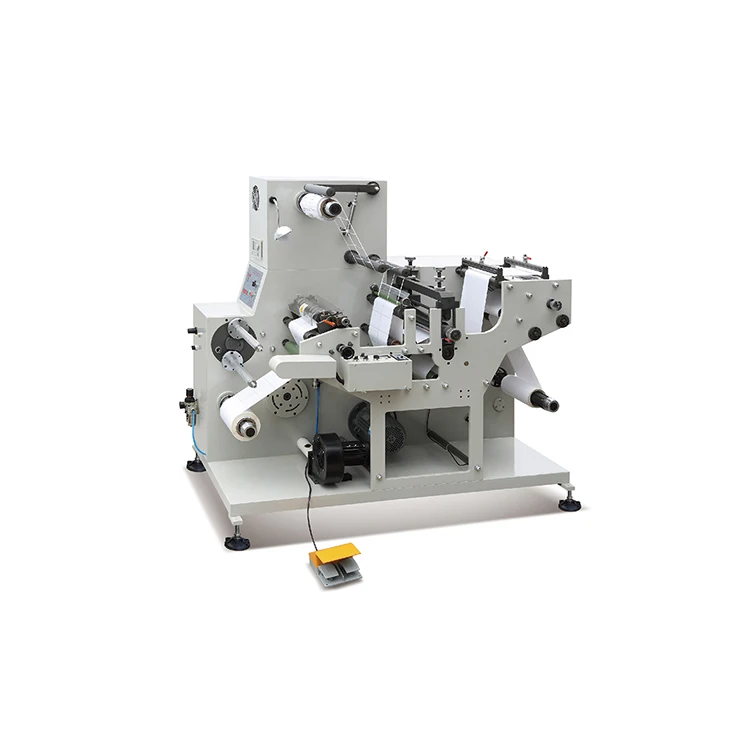

Flexographic machines offer an advantage in terms of speed as it is essential to be efficient, so you find the process faster and easy. Jingle Blue’s machines are designed for speed, and to eliminate any wasted time. One key aspect of this efficiency is how rapidly we can swap out the rolls of material that the machines use. The jingle blue flexographic press have special features and it enables us to change the rolls in a matter of seconds! This cuts down on time and waste, which is nice for the planet. Working the machines is only one part; the operators must also ensure that everything is tidy and organized. They have to switch parts like the rollers frequently to maintain the machines. These guidelines ensure Jingle Blue's flexographic products operate at their finest, producing quality prints for us all to enjoy.

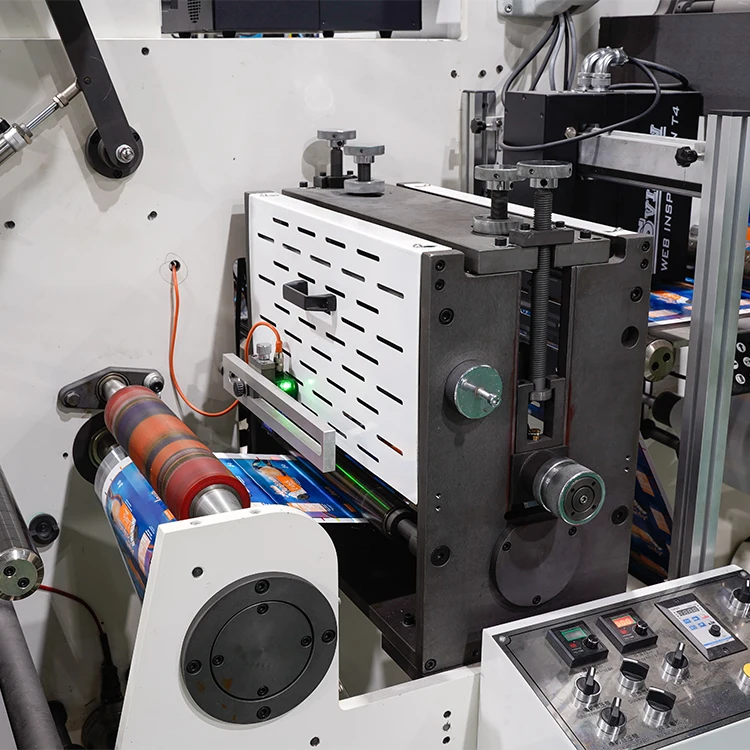

Flexographic printing technology is very versatile, allowing it to be used for a wide variety of applications. The flexographic machines at Jingle Blue print on materials ranging from paper to film and foil. That versatility is what makes these machines so great! Many colors and types of ink can also be used by them, including water-based inks that clean up easily as well as UV-curable inks that dry quickly. With hundreds of options available, Jingle Blue's machines can create everything from premium stickers you might find on a bottle to rugged packaging that protects our snacks.

Flexographic printing technology is very versatile, allowing it to be used for a wide variety of applications. The flexographic machines at Jingle Blue print on materials ranging from paper to film and foil. That versatility is what makes these machines so great! Many colors and types of ink can also be used by them, including water-based inks that clean up easily as well as UV-curable inks that dry quickly. With hundreds of options available, Jingle Blue's machines can create everything from premium stickers you might find on a bottle to rugged packaging that protects our snacks.

Flexo machines completely transformed product life & the way brands brought their products to customers. It can be in a cardboard box (which Jingle Blue's advanced machines can print on) or in plastic bags, or metal. While making it easier for brands to sell you their products. They can print custom designs, enticing logos and even QR codes right on their packaging. It makes it less complicated for customers to discover more concerning the item or where to buy it. Whether the printing done by jingle blue flexo printing machine to help companies stand out on the shelves in stores and be more competitive in the market.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog