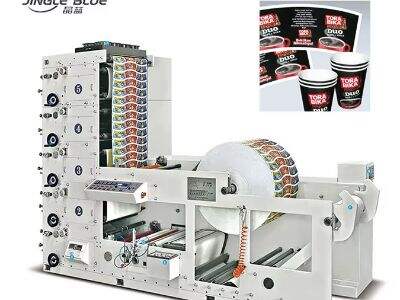

High-Speed Flexo Presses For High Volume Packaging Production

Flexographic printing presses employ flexible printing plates to spread ink onto packaging substrates. They are well-regarded for their fast and efficient nature, and therefore are often a machine of choice when there’s a big order that needs to get filled quickly. Jingle Blue brings unmatched flexo print technology to ensure that your packaging runs are treated with absolute perfection.

Optimize Performance with Flexo Printing Machines for BB Orders

If you have a big packaging job that requires a fast turn-around, Jingle Blue's flexo printing presses are for you! They’re built to maximize uptime, so you can get your products out the door as quickly as possible.

With flexo printing machines for your large packaging runs, you can guarantee that each package will always printed of the same quality. This is crucial to preserve the integrity of your brand and make sure your customers get great products every time they order from you.

Advantages of Flexo Printing Machines for Bulk Packaging Jobs

Certainly, there are advantages to using flexo printing machines for bulk packaging work. These machines are not just fast but are also precise when it comes to print as well as flexible. Here are the materials you can print on using JingleBlue flexo printing machines: paper, cardboard, and plastic.

Another way that bulk packaging jobs are made cheaper by using flexo printing machines is simply the cost savings. These machines are capable of printing a very high quality image at a fraction of the cost of other print methods which makes them an expensive option for large quantities.

High-Volume Packaging Job Tips with Flexo Presses

If you want to have successful large volume packing runs with flexo printing machines, here are a few guidelines you should follow. First, you need to ensure that you are properly calibrating the machine before starting a new job. So that there won’t be any problems with the printing and the packaging process will run as smoothly.

And also make sure the inks and materials are of very high-quality flexographic machine when running large packaging quantities. So you can be ensured that your prints will have the best possible vibrancy and be long-lasting. Lastly, remember to maintain your flexo printing machine properly so that it continues to run effectively and smoothly.

Final word If you are looking to take care of high volume packaging runs, flexo printing machines are the answer. With the state of the art Jingle Blue technology, and the top-quality machine, you can make sure your packaging gets printed anytime, all the time, and on the go. So why wait? Get in touch with us today for more information on how our flexo printers can help your packaging runs!