The winder paper machine takes the large rolls of paper produced by the paper-making machine. Once it has received these big rolls, the winder paper machine cuts the big roll into small rolls. These smaller rolls lend themselves to a variety of uses, from notebooks to printing paper. It also eliminates the possibility of bumps and wrinkled paper on the final manufactured product. The paper is of good quality by flattening wrinkles that may take place during manufacturing and is pretty but also nice to the touch!

Imagine the time it would take to produce the paper if there were not winder machines. It would take a freaking long time, and would also cost a lot of money! That, of course, is why the winder machine is so crucial for every single paper maker. This jingle blue paper rewinder machine enables paper makers to produce a lot more paper in less time. This allows them to stay in step with the demand from people who want to purchase paper.

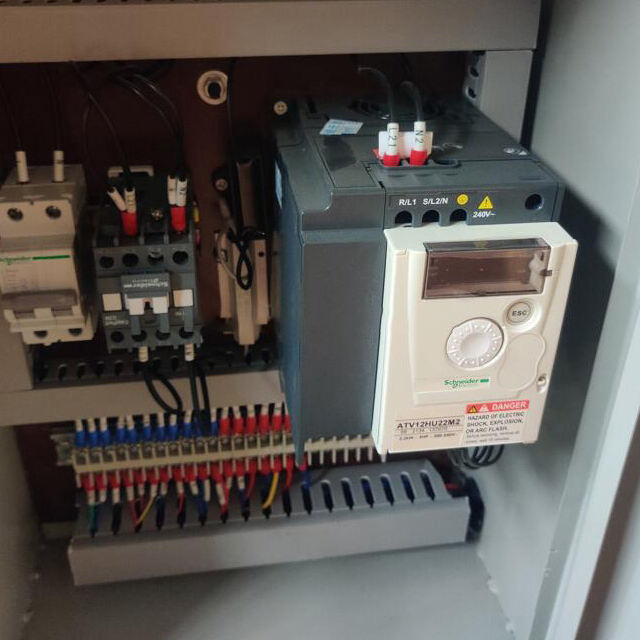

There is actually a company called Jingle Blue that manufactures these winder machines and to ride the latest technology, they have invested a lot. These tools are not common machines; they are quick cutting systems that assist you in the quick and accurate cutting of the paper. They also have good tension control, so they can ensure that the paper is rolled up just so. Also, they use special methods to set the rolls that can accelerate the entire process of producing paper. All of these capabilities serve to ease the work of the people at paper factories.

When it comes to production of paper, timing matters. Making paper faster is better for the company because it saves money and keeps customers happy, so we train you on data as far back as October 2023. That is why it is very important to have the latest machines to produce greater volumes of paper faster,” he explained. Modern winder machines, such as the ones produced by Jingle Blue, use cutting-edge technology to improve production output.

I like the fact that the winder machines here at Jingle Blue have sensors. The sensors can feel a problem with the paper, like a tear or defect. When they sense a problem, the machine instantly stops operation. That prevents the unnecessary waste of paper, which is good for the environment — and the paper-makers save money.

Consumers want quality paper, and paper mills are expected to bring it. So it's very crucial to invest in good machines that ensure the paper achieved is of the best possible quality. The jingle blue rewinder machine paper has this technology for special pressure control. Now to ensure that the paper is rolled, tight but with no damage.

The Jingle blue creates an automatic machine, controlling the angle of the shredding blade as well. The very jingle blue rewind machine has a smart feature that upgrades the cutting edge quality. The cutting blade ends should ideally be at an angle that avoids ripping or tearing of the paper edges. This level of detail ensures that the final product is ready to be used immediately.

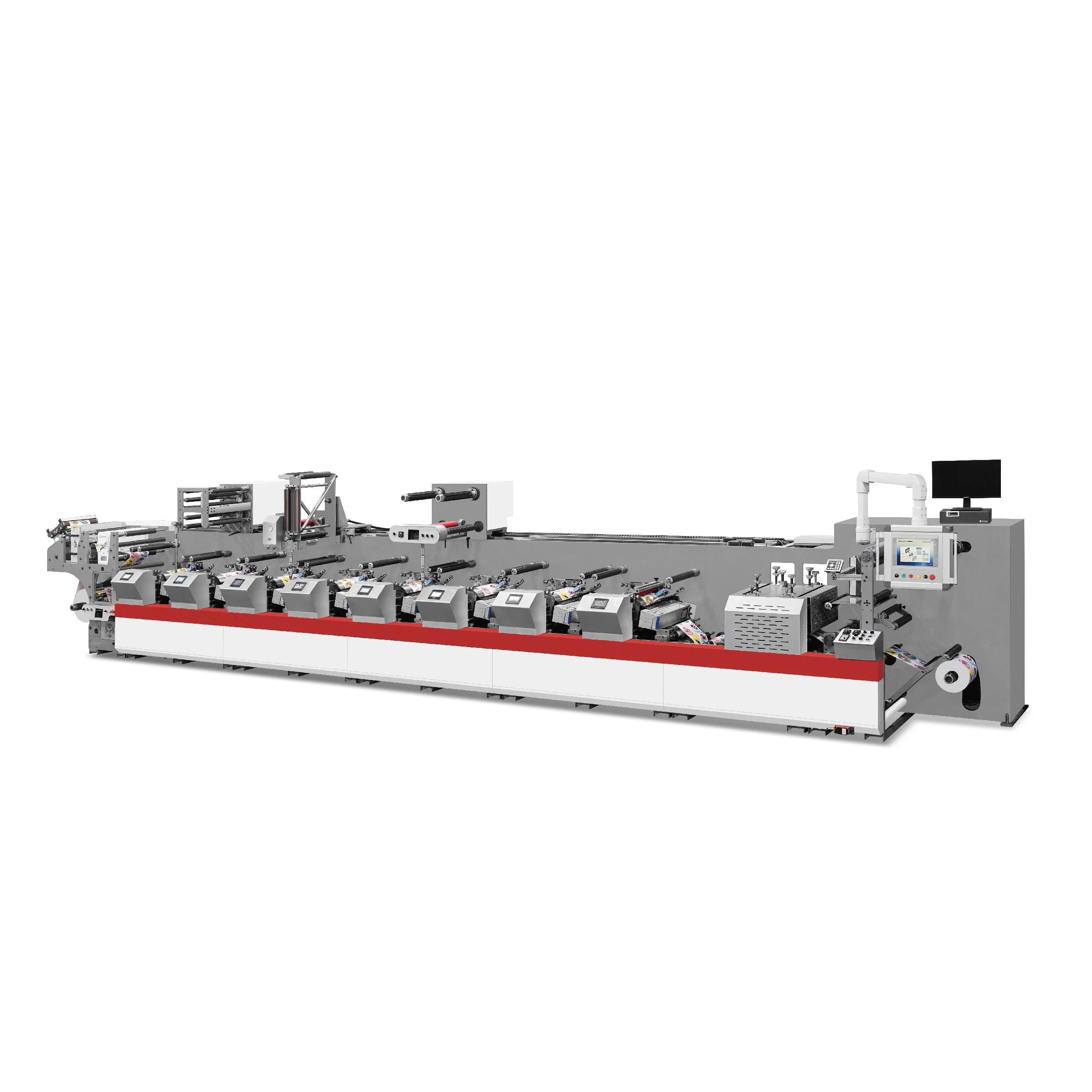

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog