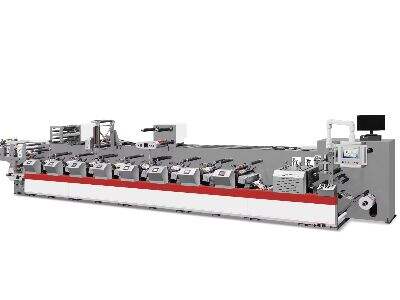

U brzom svijetu tiskanja danas, moderni fleksotisak su ključni za poduzeća kako bi učinkovito mogla zadovoljiti svoje proizvodne potrebe. Ove su strojeve vrhunske tehnologije i automatske, što povećava učinkovitost i održava tijek posla. A što je to na najnovijim fleksotisakama, dizajniranim za industrijsku uporabu, koje im omogućuju tako učinkovito izvođenje?

Produktivnost također omogućuje visoka razina tehnologije i automatizacije

Među mnogim čimbenicima koji doprinose učinkovitosti današnjih fleksotisaka je tehnologija. Oni su poboljšani moćnim značajkama i mogu se prilagoditi vašoj sadržaji radi pojednostavljenja tiskanja i povećanja produktivnosti. Automatski sustavi za doziranje tinte do sofisticiranih sustava za upravljanje bojama. Temeljito planirani moderni fleksotisak proizvode dosljedne i visokokvalitetne radove s minimalnim intervencijama. Crossman, 12-518. Poglavlje 13. Tisak mašine 13.1 Uvod 13.1 Uvod 555 13.2 Vrste fleksotisaka Sažetak Moderni fleksotisak koji ide od automatiziranih sustava za miješanje tinte do naprednih alata za upravljanje bojama dizajnirani su da proizvode dosljedne visokokvalitetne radove s malo intervencija.

Produktivnost se poboljšava i automatizacijom. Brza i precizna mogućnost postavljanja i skoro trenutna promjena poslova omogućavaju operaterima fleksibilan rad. Ovo nije samo ušteda vremena, već također doprinosi ukupnoj količini u pogledu proizvodnje prese. Opštena najnovijom tehnologijom i automatizacijom, Jingle blue flekso prese mogu raditi na maksimalnom kapacitetu i omogućiti tvrtkama da postignu svoje ciljeve s minimalnim naporima.

Visoka učinkovitost proizvoda proizlazi iz našeg preciznog inženjeringa i kvalitete upotrijebljenih materijala.

Precizna tehnologija i čvrsti materijali značajno doprinose učinkovitosti današnjih flekso presa. Linija flekso presa jingle blue dizajnirana je za izdržljivu industrijsku upotrebu koristeći komponente dugog vijeka trajanja. Od cilindara izrađenih preciznom obradom do superiornog tipa izrađenog pomoću kalupa i ploča za tisak, cijela presa je usavršena za posvećen rad i visoke performanse.

Zahvaljujući visokokvalitetnoj izgradnji i preciznom inženjeringu, Jingle blue FFGN pisači su dizajnirani da rade na najvišem nivou – omogućavajući jasne, oštre, bojne ispise u svakom poslu. Ovo ne poboljšava samo kvalitetu ispisanih proizvoda, već također smanjuje otpad i potrebu za popravcima. Kod Jingle blue fleksotisaka jednostavno znate da su napravljeni da traju i da rade na najvišem nivou.

Svuda prisutni procesi i digitalni tijekovi rada za povećanu učinkovitost

Razina automatizacije, uz novu tehnologiju i materijale visoke kvalitete, nije jedini faktor koji utječe na učinkovitost moderne fleksotisak mašine: racionalizirana proizvodnja kao i digitalizirani procesi ključni su za uspjeh. Fleksotisak mašine Jingle blue dizajnirane su tako da olakšaju tiskarske operacije, od pripreme posla do određenog softvera, a digitalna kontrola ugrađena je u mašinu kako bi pojednostavila tiskarske operacije. Kada su procesi digitalizirani, operateri mogu preuzeti kontrolu nad zadacima, pratiti status poslova i odmah izvršiti promjene kako bi optimizirali rezultate.

Digitalni radni procesi također omogućuju tvrtkama da povežu svoje fleksografске strojeve s drugim sustavima, uključujući softver za upravljanje bojama i softver za automatizaciju. Bezprekoran prijelaz između terena i ureda smanjuje pogreške, potiče dobru komunikaciju i osigurava da svaki posao bude uspješan i dovršen na vrijeme. Jingle blue fleksografски strojevi omogućuju tvrtkama da iskoriste učinkovite i digitalne radne procese koji poboljšavaju produktivnost.

Poboljšanja produktivnosti pokreću neprekidna inovacija i nadogradnje.

U brzom svijetu tiskanja kakav je danas, ovo je jedan oblik utrke u inovacijama. Jingle blue: neprekidno poboljšanje Jingle blue dosljedno uvodi nove značajke i nadograđuje svoje fleksografске strojeve, što sve doprinosi povećanju učinkovitosti proizvodnje. Ispunjavajući zahtjeve tehnologijom, Jingle blue nudi vrhunske performanse u svojim strojevima, pružajući našim kupcima najbolje alate u industriji, temeljene na potrebama tržišta.

Jingle blue flexo tiskarske mašine redovito se unapređuju i razvijaju kako bi tiskale brže, bile opremljene suvremenim sustavima upravljanja bojama i radile još učinkovitije. Ovo trajno poboljšanje omogućuje poduzećima da zadrže konkurentsku prednost i glatko ostvare svoje proizvodne ciljeve. Kada investiraju u Jingle blue flexo tiskarske mašine, korisnici mogu biti sigurni da ulažu u stroj dizajniran za budućnost, pun najnovijih značajki i tehnologija koje će im pomoći da postižu sve veće razine produktivnosti.

Izlaz tiskarske mašine poboljšava se obukom operatera i tehnikama optimizacije

Na kraju, obuka operatora i strategije optimizacije ključni su za postizanje maksimalnog učinka savremenih fleksotisaka. Jingle blue vas podržava programima obuke koji osiguravaju da operatori dobro poznaju svoje tiskare, od osnova do održavanja. Pravilnom obukom, kompanije mogu osigurati da njihovi operatori imaju potrebne vještine, prosudbu i znanje za vožnju tiskara s maksimalnom učinkovitošću.

Preventivno održavanje i analiza tiskovnih tokova su još dve strategije optimizacije koje mogu pomoći kompanijama da maksimalizuju ulaganje u fleksotiskare, izvan obuke zaposlenih. Uvođenjem poboljšanja procesa i otklanjanjem nedostataka, kompanije mogu maksimalizirati proizvodnju tiskara i ostvariti pogodnosti u pogledu produktivnosti. S fleksotiskarima Jingle blue, poslovne subjekte mogu iskoristiti obuku operatora i pristupe optimizaciji kako bi optimizovali izlaz tiskara i osigurali kontinuiran i učinkovit rad.

Dakle, evo vam: rOTACIJSKI STROJ ZA PRESIJEČANJE UZORKA mješavina redovne tehnologije, preciznog inženjerstva, učinkovitih procesa, kontinuirane inovacije i stručnih operatera. Predstavljamo seriju fleksografskih tiskara jingle blue - bez ograničenja za produktivnost i učinkovitost. S fleksografskom tiskarom Jingle (Blue), tvrtke znaju da dobivaju stroj koji je konstruiran za brzinu i izrađen kako bi poboljšao produktivnost.

Table of Contents

- Produktivnost također omogućuje visoka razina tehnologije i automatizacije

- Visoka učinkovitost proizvoda proizlazi iz našeg preciznog inženjeringa i kvalitete upotrijebljenih materijala.

- Svuda prisutni procesi i digitalni tijekovi rada za povećanu učinkovitost

- Poboljšanja produktivnosti pokreću neprekidna inovacija i nadogradnje.

- Izlaz tiskarske mašine poboljšava se obukom operatera i tehnikama optimizacije