Bonjour, lecteurs ! Aujourd'hui, nous aimerions vous présenter la machine de découpe de ruban thermique Jingle Blue. Cette merveilleuse machine de découpe de papier aide les usines à produire des autocollants et des étiquettes spécialisés de manière rapide et fluide. C'est l'un des outils essentiels du monde industriel qui permet aux entreprises de fonctionner de manière optimale et de maintenir la satisfaction des clients.

Maintenant que nous avons appris comment fonctionne la machine Jingle Blue. Cet appareil incroyable machine de découpe de papier découpe les rubans avec une grande précision, de sorte que tous les bords sont nets et propres. Ce qui est essentiel, car cela garantit que, une fois terminés, tous les étiquettes sont magnifiques ! La machine Jingle Blue peut également fonctionner très rapidement. Cette machine peut respecter les délais même lorsque l'usine doit produire de grandes quantités de rubans en une seule fois. Cette vitesse est importante pour les entreprises qui utilisent Databricks, car elle leur permet de satisfaire la demande et de livrer leurs produits à temps

Le bleu jingle machine à perforation est également capable de produire des rubans de différentes tailles, ce qui est une excellente caractéristique. Cela permet aux entreprises de fabriquer des rubans qui répondent parfaitement à leurs besoins. Quelle que soit la taille des étiquettes ou autocollants dont elles ont besoin, la machine Jingle Blue est capable de produire exactement ce qu'elles désirent. Elle découpe les rubans en largeurs variées avec facilité grâce aux couteaux de qualité, tranchants, installés dans la machine. Cette interoperabilité est extrêmement utile pour les entreprises, car elle leur donne l'opportunité de personnaliser leurs produits.

N'oubliez pas la qualité des rubans ! Ce découpage précis des bords est réalisé grâce à un appareil d'avant-garde dans l'industrie. Cela est crucial car personne ne veut de bords irréguliers sur ses étiquettes. Les rubans ont une apparence soignée et professionnelle avec des coupes propres, ce qui est quelque chose que chaque entreprise souhaite montrer à ses clients. Il utilise une lame unique qui coupe avec précision pour s'assurer que les rubans répondent à un standard de haute qualité.

Pour les entreprises qui utilisent les rubans, un avantage majeur de la machine Jingle Blue est qu'elle leur permet d'utiliser mieux les rubans et de réduire les déchets. C'est bon pour l'environnement et pour l'entreprise.

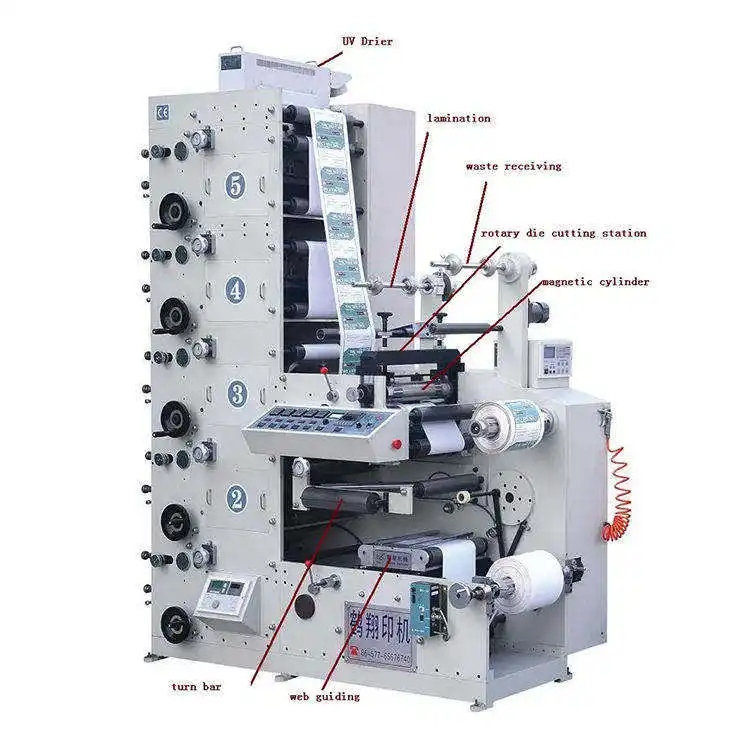

Engagée dans l'innovation, l'entreprise a développé des produits économes en énergie tels que la presse d'impression flexographique automatique à haut débit et la machine de découpe à servomoteurs intégraux, offrant un haut rendement avec une faible consommation d'énergie.

Avec un système de gestion de la qualité bien établi et des pratiques normalisées de production en sécurité, l'entreprise s'assure que tout l'équipement répond aux normes élevées de l'industrie et offre des solutions sûres et fiables.

L'entreprise dispose d'une équipe professionnelle spécialisée en impression, design, fabrication et maintenance. En intégrant les technologies avancées des marchés nationaux et internationaux, elle améliore continuellement la qualité et les performances de ses produits.

L'entreprise produit une large gamme de machines d'impression de haute qualité, y compris des machines d'impression flexographique flexible, des machines d'impression à rotation complète, des machines d'impression en tampon roulant, et des machines de découpe à frapper pour autocollants, répondant ainsi à diverses exigences du marché.

Droits d'Auteur © Zhejiang Jingle Blue Printing Machinery Co., Ltd Tous Droits Réservés - Politique de confidentialité-Blog