– Un type d'imprimante capable d'imprimer des images vives et multicolores sur divers matériaux. L'impression Flex est principalement utilisée pour imprimer des boîtes en carton, des sacs en plastique et des tissus pour vêtements. Dans ce guide, nous apprendrons tout sur la façon dont les imprimantes ont transformé le monde de l'impression et ce dont elles sont capables. Nous examinerons également comment imprimantes sont utilisés de manière diversifiée, et comment les dernières machines rendent l'impression meilleure et plus rapide que jamais.

Les imprimantes sont devenues les pionnières de l'impression graphique flexible , remplaçant des méthodes comme l'impression par gravure ou typographique. Ces méthodes étaient souvent très chronophages et coûteuses. De plus, l'impression se limitait à quelques couleurs disponibles, ce qui rendait plus difficile la création de conceptions colorées.

Depuis son apparition au début des années 1900, la technologie d'impression a évolué, permettant aux imprimantes de produire des impressions de qualité, d'utiliser une gamme variée de couleurs et de travailler avec de nombreux types de matériaux différents. Par exemple, les imprimantes modernes ont la capacité d'imprimer sur du plastique flexible, des surfaces à fort brillant, voire des matériaux texturés.

les imprimantes sont utilisées dans divers secteurs pour des applications variées. En ce qui concerne l'obtention de conceptions colorées sur des boîtes en carton, des sacs en plastique et des étiquettes. Cela rend visuellement les produits très attractifs pour les clients et aide au rappel de la marque en concevant des motifs personnalisés pour le tissu.

Si plus de personnes souhaitent des impressions de haute qualité, les machines ont effectivement évolué avec le temps. Ces machines disposent désormais d'un calibrage automatique des couleurs, ce qui signifie que chaque couleur est imprimée exactement là où elle doit l'être à chaque fois. Non seulement cela économise du temps, mais cela réduit également les déchets, rendant le processus plus efficace. L'impression écologique parce qu'elle réduit également la quantité totale d'encre utilisée. Atteindre une réduction de leur empreinte écologique et devenir plus respectueux de l'environnement.

L'entreprise dispose d'une équipe professionnelle spécialisée en impression, design, fabrication et maintenance. En intégrant les technologies avancées des marchés nationaux et internationaux, elle améliore continuellement la qualité et les performances de ses produits.

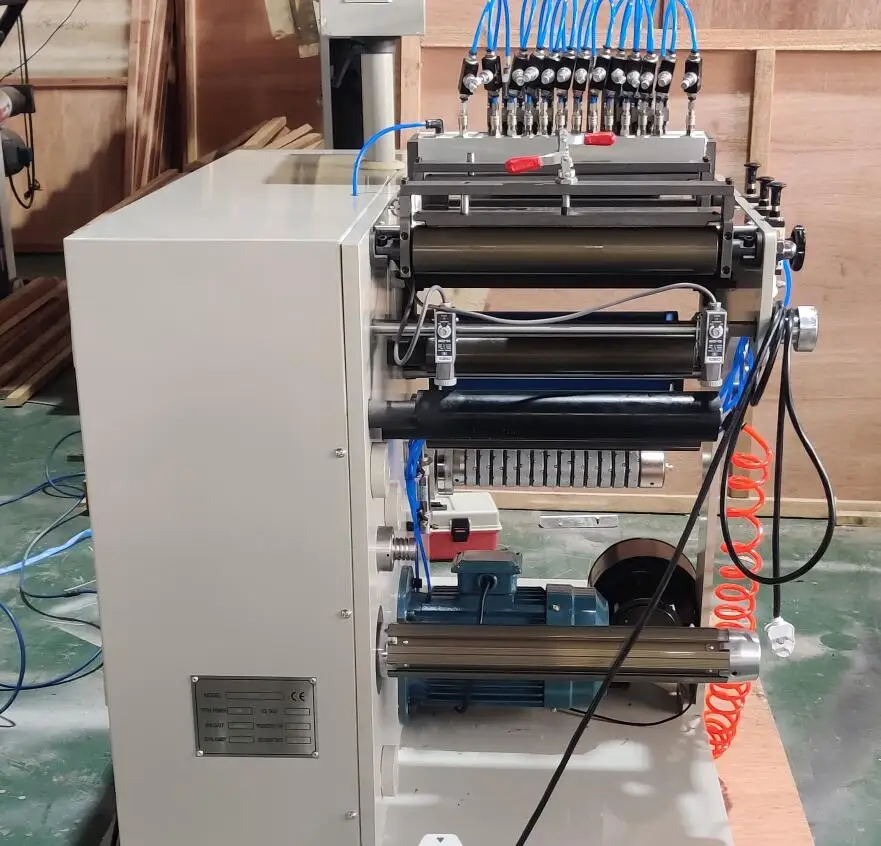

L'entreprise produit une large gamme de machines d'impression de haute qualité, y compris des machines d'impression flexographique flexible, des machines d'impression à rotation complète, des machines d'impression en tampon roulant, et des machines de découpe à frapper pour autocollants, répondant ainsi à diverses exigences du marché.

Avec un système de gestion de la qualité bien établi et des pratiques normalisées de production en sécurité, l'entreprise s'assure que tout l'équipement répond aux normes élevées de l'industrie et offre des solutions sûres et fiables.

Engagée dans l'innovation, l'entreprise a développé des produits économes en énergie tels que la presse d'impression flexographique automatique à haut débit et la machine de découpe à servomoteurs intégraux, offrant un haut rendement avec une faible consommation d'énergie.

Droits d'Auteur © Zhejiang Jingle Blue Printing Machinery Co., Ltd Tous Droits Réservés - Politique de confidentialité-Blog