Η στροφική διαδικασία διακοπής είναι μια τεχνολογία κρίσιμη για την κατασκευή ηλεκτρονικών. Η διαδικασία χρησιμοποιεί ένα στρογγυλό τεμάχιο που περιστρέφεται για να κόψει και να διαμορφώσει το υλικό με ακρίβεια, συμπεριλαμβανομένων μετάλλων, πλαστικών και χαρτιού. Καθώς η τεχνολογία βελτιώνεται, η στροφική διακοπή προσαρμόζεται για να παράγει περισσότερους τύπους ηλεκτρονικών. Σε αυτό το blog, εξερευνούμε τον ρόλο της στροφικής διακοπής στη μετατροπή ηλεκτρονικών συσκευών.

Ο Αιώνας

Σημαντικές πρόοδοι στην τεχνολογία κοπής με περιστροφικό δίσκο έχουν μεταμορφώσει την παραγωγή ηλεκτρονικών εξαρτημάτων τα τελευταία χρόνια. Αυτές οι αλλαγές καθιστούν την παραγωγή ηλεκτρονικών εξαρτημάτων γρήγορη, ακριβή και εύκολη. Μια σημαντική καινοτομία είναι η κοπή με λέιζερ, η οποία είναι πιο ακριβής και ευέλικτη σε σχέση με παλαιότερες μεθόδους. Ένα πρόσθετο πλεονέκτημα της κοπής με λέιζερ είναι ότι μπορεί να δημιουργεί μικρά, λεπτομερή σχήματα με ελάχιστα απόβλητα, κάτι ιδανικό για τα πολύ μικρά ηλεκτρονικά.

Μια άλλη βελτίωση είναι η χρήση ρομπότ και μηχανών για να γίνεται η διαδικασία πιο γρήγορα και ακριβέστερα. Αυτά τα αυτοματοποιημένα συστήματα κοπής με περιστροφικό δίσκο μπορούν να λειτουργούν γρήγορα και να μειώνουν τα λάθη, βελτιώνοντας την παραγωγή. Με αυτές τις προόδους, οι κατασκευαστές ηλεκτρονικών μπορούν να παράγουν περισσότερα εξαρτήματα πιο γρήγορα και με υψηλότερη ποιότητα.

Επιβραδύνοντας την Παραγωγή με Μεγαλύτερη Ακρίβεια

Για τον λόγο αυτό, η περιστροφική διάτρηση είναι αποφασιστικής σημασίας για την παραγωγή ηλεκτρονικών με πιο γρήγορο και ακριβές τρόπο. Με τις γρήγορες μηχανές περιστροφικής διάτρησης, τα ηλεκτρονικά εξαρτήματα μπορούν να παραχθούν με αποτελεσματικό και ακριβή τρόπο. Επιπλέον, μπορούν να χρησιμοποιηθούν πολύ μικρές μετρήσεις (μικρόμετρα) για να γίνει η διάτρηση, εξασφαλίζοντας ότι το κάθε εξάρτημα πληροί τα απαιτούμενα πρότυπα.

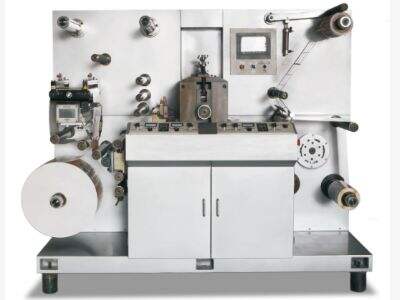

Η περιστροφική διάτρηση επιτρέπει στους κατασκευαστές να επιτυγχάνουν τα ίδια εξαιρετικά αποτελέσματα, παράγοντας ταυτόχρονα μεγάλο όγκο προϊόντων, κάτι που δημιουργεί πολύ λιγότερο περιθώριο για λάθη. Αυτό το επίπεδο ακρίβειας είναι αποφασιστικής σημασίας, καθώς η βιομηχανία ηλεκτρονικών εξελίσσεται συνεχώς και τα πρότυπα ποιότητας είναι πολύ υψηλά. Η περιστροφική Μηχανή κοπής μήτρας βοηθά τους κατασκευαστές να προηγηθούν των συναδέλφων τους και να παραδίδουν εξαιρετικές ηλεκτρονικές συσκευές με επάρκεια και αποτελεσματικότητα.

Περιστροφική Διάτρηση: Η Λύση για τη Βιομηχανία Ηλεκτρονικών

Η αυξημένη ζήτηση για προηγμένα και αξιόπιστα προϊόντα δημιουργεί περισσότερες ευκαιρίες ανάπτυξης για τη βιομηχανία ηλεκτρονικών. Οι δημιουργοί πρέπει να κατασκευάζουν ηλεκτρονικά εξαρτήματα που είναι τόσο προηγμένα όσο και αξιόπιστα. Ακριβώς αυτή τη ζήτηση υποστηρίζει η τεχνολογία κοπής με περιστρεφόμενο έμβολο — παρέχει στους κατασκευαστές τα απαραίτητα εργαλεία για να κατασκευάζουν αποδοτικά ηλεκτρονικά εξαρτήματα με αποτελεσματικότητα.

ΜΗΧΑΝΗ ΕΠΙΧΕΙΡΗΣΙΑΚΟΥ ΚΟΠΗΣ ΜΕ ΓΥΡΝΟΥΣΑ ΣΦΡΑΓΙΔΑ είναι επίσης εύκαμπτη ως προς την παραγωγή, εκτός από το ότι ενισχύει την ταχύτητα και την ακρίβεια. Οι κατασκευαστές μπορούν εύκολα να μεταβαίνουν από ένα υλικό σε άλλο και από ένα στοιχείο σχεδίασης σε άλλο· αυτή η ευελιξία τους επιτρέπει να αντιδρούν γρήγορα στις απαιτήσεις των πελατών. Σε μια βιομηχανία που κινείται γρήγορα, η ευελιξία είναι κομβική και μπορείτε να είστε τόσο δυναμικοί όσο χρειάζεται και να μεγεθύνετε την ομάδα σας ανάλογα.

Προόδους στην τεχνολογία περιστροφικής διαγωνιοποίησης: περισσότερες προσαρμοσμένες επιλογές ηλεκτρονικών. Πλέον, οι κατασκευαστές μπορούν να σχεδιάζουν εξαρτήματα που έχουν κατασκευαστεί ειδικά για να καλύπτουν τις ανάγκες των πελατών τους, χωρίς να χάνεται απόδοση. Αυτά τα χαρακτηριστικά βοηθούν τους κατασκευαστές ηλεκτρονικών να ξεχωρίζουν και να καλύπτουν τις διαφορετικές ανάγκες των καταναλωτών.

Μια σημαντική πρόοδος έχει να κάνει με την εξέλιξη πολυλειτουργικών συστημάτων διαγωνιοποίησης. Αν και αυτά τα συστήματα μπορούν να κόβουν, να αναγλυφώνουν και να διατρέχουν υλικό ταυτόχρονα, κερδίζοντας έτσι χρόνο και χρήμα. Οι κατασκευαστές μπορούν επίσης να επεκτείνουν τη δημιουργικότητα τους όταν χρησιμοποιούν στρώματα προηγμένων υλικών, όπως ειδικευμένες μελάνια και επιστρώσεις, μέσα στις δημιουργίες τους κοπή με περιστρεφόμενο έμβολο μηχανή διαδικασίες.