και την ανατύλιξη. Η Jingle Blue εκτυλίσσει το χαρτί και είναι αρκετά καλή στην ανατύλιξη...">

Πολύ ωραίο να διαβάζεις γι' αυτό μηχανήματα κοπής χαρτιού ξετύλιγμα. Η Jingle Blue παράγει χαρτί και είναι αρκετά καλή στο ξετύλιγμά του. Συνεχίστε να διαβάζετε για να μάθετε περισσότερα σχετικά με την τέχνη και τη διαδικασία του ξετυλίγματος χαρτιού, γιατί είναι τόσο απαραίτητη, πού εντάσσεται στη διαδικασία παραγωγής χαρτιού και ορισμένες τεχνικές χειρισμού ρολών χαρτιού.

Η διαδικασία παραγωγής του είναι παρόμοια με το να τυλίγεις ένα λάστιχο αφού το τεντώσεις. Πρόκειται για τη διάσπαση μεγάλων ρολών χαρτιού σε κάτι μικρότερο και πιο εύχρηστο. Το κάνει καλά γιατί θέλουν το χαρτί τους να είναι το καλύτερο, λόγω όλων των διασκεδαστικών πραγμάτων που μπορείς να κάνεις μαζί του.

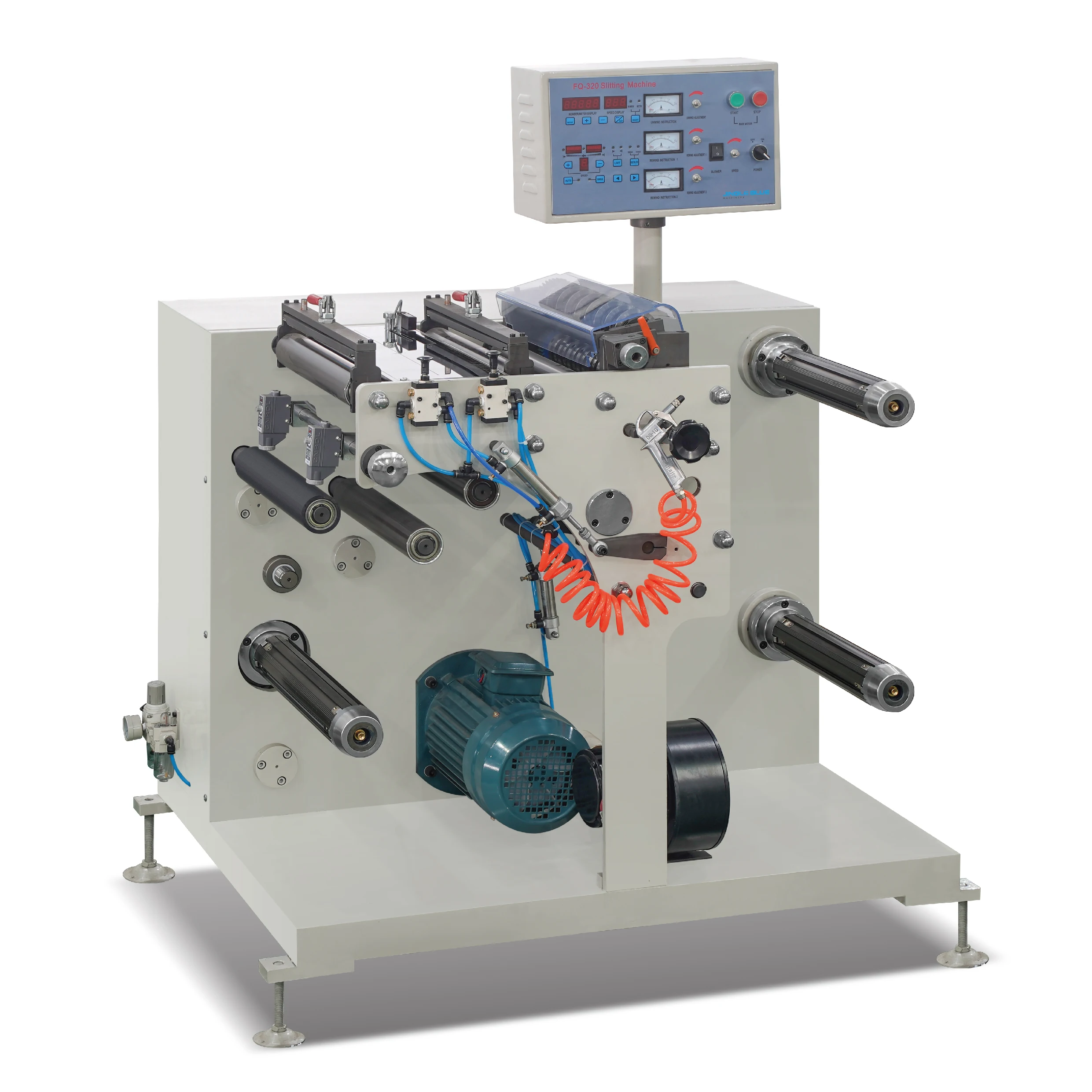

Στην αναμεταφορά Jingle Blue μηχανή κοπής χαρτί με ψαλίδα χρειάζεστε μια ειδική μηχανή που ανεμίζει απαλά το χαρτί ξανά. Το μεγάλο μαγούλι χαρτί τοποθετείται πρώτο στη μηχανή. Η μηχανή στη συνέχεια ξετυλίγει το χαρτί και το κόβει σε μικρότερα μαγουλάκια. Αυτά τα μικρά μαγουλάκια τυλίγονται ξανά πιο σφιχτά, για να έχουμε ένα όμορφο και καθαρό μαγούλι έτοιμο για σχέδιο, γραφή ή κατασκευή.

Το Jingle Blue εμποδίζει οι σελίδες να μην έχουν το σωστό μέγεθος για διάφορες χρήσεις, καθώς επιτρέπει στους χρήστες να ξαναγυρίσουν πίσω μηχανή σπάσιμου χαρτιού . Έτσι γίνεται πιθανή εξοικονόμηση κόστους και χώρου γι’ αυτούς, αφού δεν χρειάζεται να βρουν χώρο για να αποθηκεύσουν μεγάλους κυλίνδρους χαρτιού που ίσως ή όχι να χρησιμοποιηθούν. Είναι επίσης λιγότερο ενοχλητικό για το προσωπικό να χειρίζεται το χαρτί χωρίς να το χαλάσει.

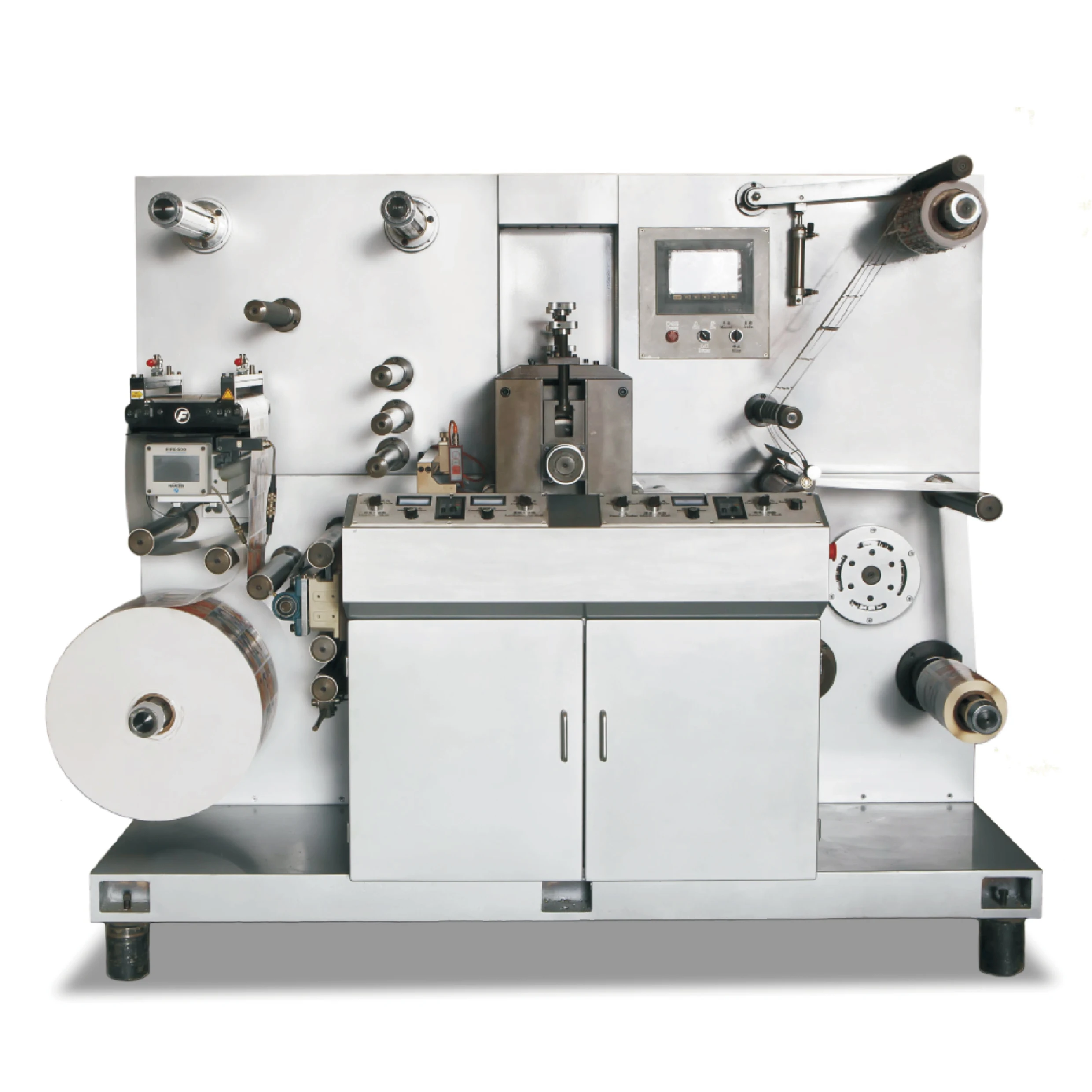

Η επιχείρηση χαρτιού είναι σαν έναν τεράστιο κύκλο που συνεχώς περιστρέφεται. Αρχικά, σε ένα χαρτοποιείο, το ξύλο μετατρέπεται σε χαρτί. Το μηχανή κοπής ρολόιων χαρτιού στη συνέχεια ξαναγυρίζει σε κυλίνδρους που μπορούν να σταλούν σε καταστήματα. Καθώς οι άνθρωποι χρησιμοποιούν το χαρτί, χρειάζεται να αγοράσουν περισσότερο. Αυτό ξεκινάει ξανά τον κύκλο.

Κύλινδρος σπάταλας χαρτιού μπορεί να είναι δύσκολο να χειριστεί κανείς, γιατί είναι μεγάλος και βαρύς. Χρησιμοποιούνται ειδικά εργαλεία για να μετακινούνται οι κύλινδροι με ασφάλεια και να διατηρούνται σε καλή κατάσταση, αναφέρεται. Επίσης, πρέπει να προσέχουν να μην αφήσουν τους κύλινδρους να πέσουν ή να προκληθεί ζημιά, γιατί το χαρτί μπορεί να μην ξαναγυρίσει καλά.

Η εταιρεία παράγει ευρύ φάσμα υψηλής ποιότητας μηχανών τυπογραφίας, συμπεριλαμβανομένων των ευέλικτων μηχανών χαρακτηροτυπίας, των πλήρων μηχανών περιστροφικής τυπογραφίας, των μηχανών οθόνης τυπογραφίας από κύλινδρο σε κύλινδρο και των μηχανών κοπής κολλών σημειώσεων, καλύπτοντας διάφορες απαιτήσεις της αγοράς.

Με ένα καλά ιδρυμένο σύστημα διαχείρισης ποιότητας και τυπικές πρακτικές ασφαλούς παραγωγής, η εταιρεία εξασφαλίζει ότι όλα τα εξαρτήματα ανταποκρίνονται σε υψηλά βιομηχανικά πρότυπα και παρέχουν ασφαλείς και αξιόπιστες λύσεις.

Επικεντρωμένη στην καινοτομία, η εταιρεία έχει αναπτύξει οικονομικά ενεργειακά προϊόντα όπως η πλήρως αυτόματη υψηλής ταχύτητας μηχανή εκτυπωτικής με χρήση φλεξογραφίας και η πλήρως διακομιδιακή μηχανή κοπής, προσφέροντας υψηλή απόδοση με χαμηλή κατανάλωση ενέργειας.

Η εταιρεία καυχάται μιας επαγγελματικής ομάδας με δεξιότητες στην τυπογραφία, σχεδιασμό, κατασκευή και διαφύλαξη. Με την ενσωμάτωση προηγμένων τεχνολογιών από τις εθνικές και διεθνείς αγορές, επιμένουν να βελτιώνουν συνεχώς την ποιότητα και τις αποδόσεις των προϊόντων τους.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd. Όλα τα δικαιώματα κατεχόμενα - Πολιτική απορρήτου- Τι;Ιστολόγιο