Rotationsstanzschneider mig...">

Haben Sie sich jemals gefragt, wie Ihre Lieblingsbänder, Etiketten oder Aufkleber hergestellt werden? Im Grunde beginnt alles mit dieser Aufwickel- und Abwickelmaschine. Sie rotary-Schneidemaschine könnten sich fragen, was eine Aufwickel- und Abwickelmaschine überhaupt ist und warum sie wichtig ist? Zum Beispiel nimmt eine solche Maschine eine Rolle mit Klebeband auf und wickelt es dann auf eine andere Rolle um.

Dies geschieht, weil die Maschine den Materialverbrauch durch eine präzise Schnittanpassung minimiert. Durch das Schneiden in der exakten Größe paper slitter die benötigt wird, anstatt der nächsten Standardbreite, bewahrt die Maschine wertvolle Ressourcen (wie Bänder, Etiketten oder Aufkleber). Es bedeutet auch weniger Zeit, die manuell zum Schneiden verbracht wird, was langwierig und zeitaufwendig sein kann.

Um wirklich zu verstehen, wie eine Unwind-Rewindmaschine funktioniert, stellen Sie sich einfach vor, sie sei ein Drucker. Aber anstatt Tinte auf Papier zu drucken, folie auf einer frischen Rolle. Es beginnt mit einer Hauptspule, in der der Rohstoff gelagert wird. Die Maschine zieht das Material von dieser Rolle. Als nächstes wird das Material durch eine Reihe großer Rollen geleitet, die es gerade halten. Diese Rollen sind entscheidend, um sicherzustellen, dass das Material gerade bleibt und reibungslos durch die Maschine fließt.

Eine Methode, die Zeit spart und das Herstellen von Klebeband, Etiketten und Aufklebern viel reibungsloser macht, ist das Rückwickler. Menschen verschwenden oft Zeit und Ressourcen damit, Handmaterialien zu schneiden und zu verpacken.

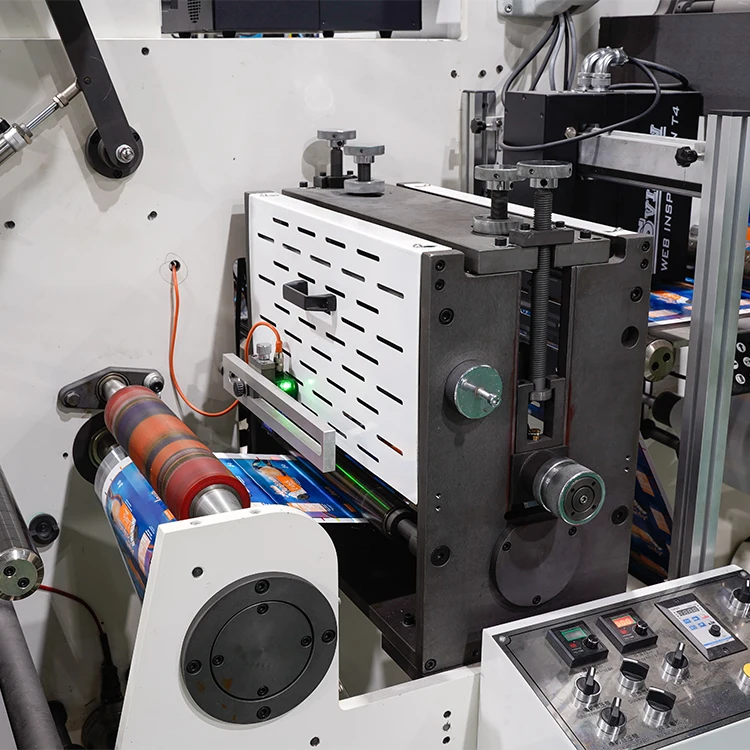

Jingle Blue ist die perfekt erklärtende Maschine zum Aufwickeln und Abwickeln, eine von mehreren, die dazu beitragen werden, Ihre Bänder besser zu konditionieren. Oktober 2023: Jingle Blue – der Name hinter der qualitativ hochwertigen Aufwickel- und Abwickelmaschine. Ideal für eine Vielzahl an Fertigungs- und Industrieaufgaben können diese Maschinen so viele Dinge tun. Sie alle werden mit höchster Qualität hergestellt, sind robust, stark und darauf ausgelegt, lange zu halten. Alle unsere Maschinen verfügen über sehr effektive und benutzerfreundliche Bedienfelder, die einen einfachen Zugriff auf alle kritischen Funktionen und Einstellungen ermöglichen.

Das Unternehmen verfügt über ein professionelles Team, das in Druckerei, Design, Fertigung und Wartung erfahren ist. Durch die Integration fortschrittlicher Technologien aus nationalen und internationalen Märkten verbessern sie kontinuierlich Qualität und Leistung ihrer Produkte.

Mit dem Fokus auf Innovation hat das Unternehmen energieeffiziente Produkte wie den vollautomatischen Hochgeschwindigkeits-Flexodruck und die Servo-Schneidmaschine entwickelt, die einen hohen Durchsatz bei niedrigem Energieverbrauch bieten.

Das Unternehmen stellt eine Vielzahl an hochwertigen Druckmaschinen her, darunter Flexoletradruckmaschinen, Vollumlaufdruckmaschinen, Roll-zu-Roll-Siebdruckmaschinen und Selbstklebe-Schneidmaschinen, um unterschiedliche Marktnachfragen zu decken.

Mit einem etablierten Qualitätsmanagementsystem und standardisierten Sicherheitsproduktionspraktiken stellt das Unternehmen sicher, dass alle Geräte den hohen Branchenstandards entsprechen und sichere, zuverlässige Lösungen bieten.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd. Alle Rechte vorbehalten - Datenschutzrichtlinie- Ich weiß.Blog