Rotující Vysekávací stroj pomáhá minimalizovat odpad během výrobního procesu. Tyto stroje řežou materiály s vysokou přesností, aby vytvářely pouze potřebné tvary. To znamená méně odpadu a více skutečných dílů. Ušetří to náklady společnostem a je to mnohem lepší pro životní prostředí, protože do skládek se dostane méně odpadu.

Rotační stříhací stroje mění způsob, jakým řežeme materiály. Tyto stroje provádějí velmi přesné řezy ve srovnání se staršími metodami, které vytvázejí velké množství odpadu. Tím spotřebují téměř celý materiál a zanechávají jen minimum, co nelze znovu použít.

Přesné řezy vedou k menšímu množství odpadu v průběhu výroby. Společnosti díky rotačním stříhacím strojům řežou materiály na skutečnou správnou velikost a tvar. To minimalizuje chyby, a proto je malé množství odpadu. Navíc přesné řezy přispívají k lepším výrobkům, protože nejsou žádné nepravidelné kusy odpadu, které by mohly pokazit finální produkt.

Rotační stříhací stroje vám pomohou minimalizovat odpad. Tyto stroje pomáhají firmám lépe nakládat s materiály. Nejenže to ušetří peníze na dlouhou trať, ale také pomáhá životnímu prostředí, protože se vylepšuje výrobní proces. ROTARY DIE CUTTING MACHINE jsou v této situaci prospěšné, protože stále více firem si přeje být odpovědná a vytvářet méně odpadu.

Rotary nůžky na stříhání jsou určeny k tomu, aby pomohly firmám pracovat rychleji, což je velkou výhodou těchto strojů. Tyto stroje řežou materiály rychleji a s větší přesností, díky čemuž mohou firmy vyrábět více produktů za kratší dobu. To znamená efektivnější využití materiálu a méně odpadu vznikajícího při výrobě. Rotary nůžky na stříhání jsou také výborné pro výrobce z hlediska úspor nákladů díky sníženému množství odpadu.

Rotary nůžky na stříhání jsou optimálním řešením pro eliminaci odpadu, když firmy usilují o ekologičtější provoz. Tato zařízení mohou pomoci při výrobě kvalitních produktů s minimálním odpadem spolu s efektivním zpracováním. To pomáhá firmám ušetřit peníze na dlouhou trať a podporuje lepší metody výroby, které přinášejí výhody jak firmám, tak i životnímu prostředí.

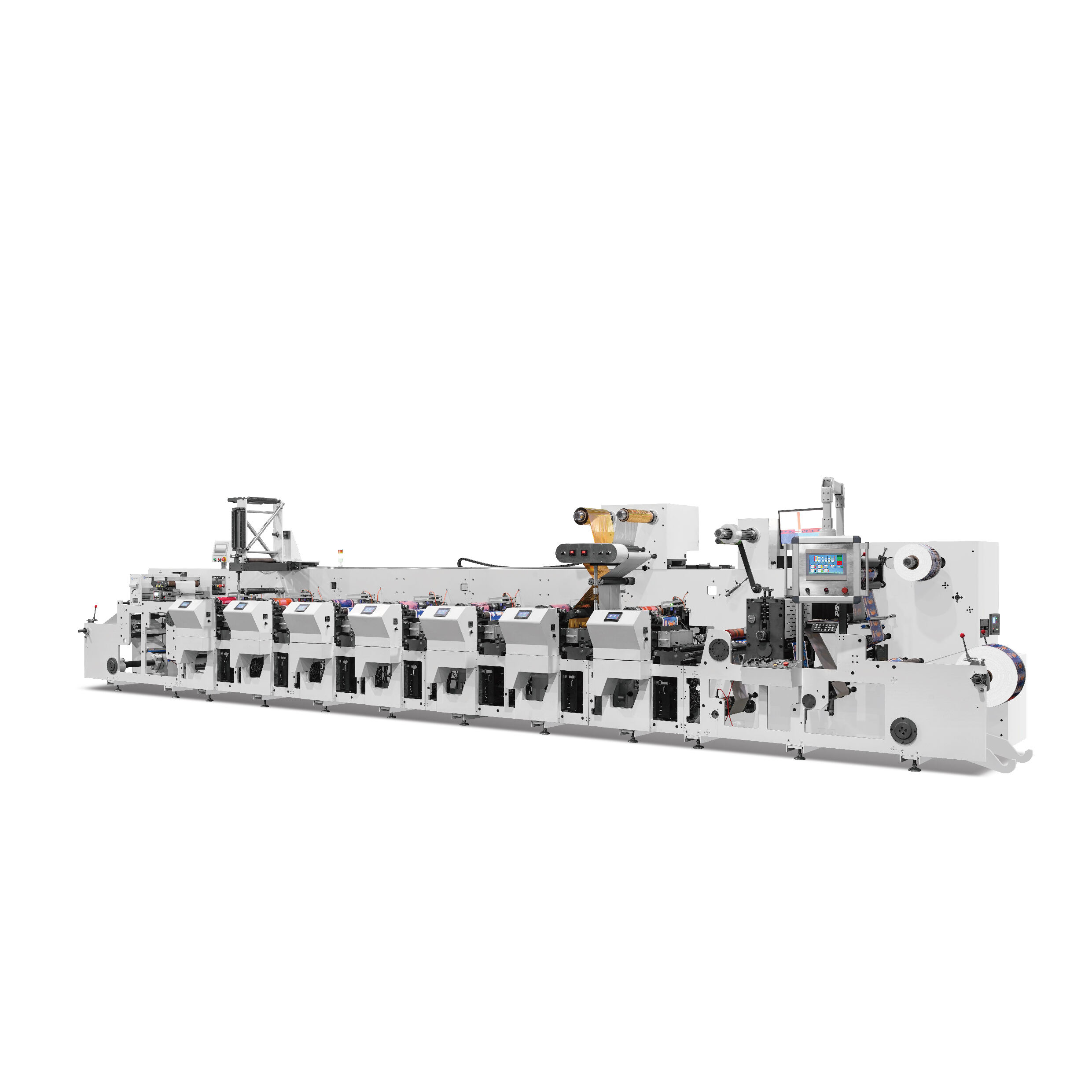

Stroje pro výstřižek rotoru jsou nezbytné pro snižování odpadu v průběhu výrobního procesu. Vysoká přesnost řezání znamená přesnější řezy s menším množstvím odpadu a zbytkového materiálu, což podporuje lepší výrobní postupy. Plošným vyřezávacím strojem také pomáhají společnostem pracovat efektivněji, minimalizovat odpad a maximalizovat jejich výrobní proces. Společnost Jingle Blue se pyšní tím, že představuje tyto stroje, které pomáhají firmám dosahovat cílů udržitelnosti a zároveň zůstávat rentabilními.