In flexo printing details such as ink are very important. The thickness of the ink, known as viscosity, can affect how good the prints look. Maintaining the viscosity, then, is crucial to ensuring that every print comes out just right.

The Importance of Uniform Viscosity in Flexo Printing

Imagine having to color in a picture with a marker that can’t make up its mind how thick its ink is. It would be difficult to make the picture look nice and neat. Flexo printing behaves similarly when the ink thickens up too much. For good prints, the ink must be the correct thickness each time.

What Determines Viscosity of Ink in Flexo?

There are several factors that can lead the ink to become thicker or thinner. For instance, temperature, humidity, and the speed with which the printer is operating can all affect ink viscosity. It’s like cooking in a way — you use too much flour in bread, the dough is too thick. In case of flexo printing, if the ink too thick or too thin then print won’t look nice.

How to examine and regulate ink viscosity during the operation of Machine in Flexo printing

A tall, hydraulic tool is used by printers to check the viscosity of the ink, to ensure it’s the proper thickness. This lets them know whether the ink should be changed before printing. If the ink is too thick, they can add a touch of thinner to get it just right. They shouldn’t throw out the ink if it is too thin, they can add something to make it thicker.

The Importance of Ink Viscosity to Achieving Quality Prints

The prints are razor sharp and full of colours when the ink viscosity is the same. If it’s too thick, your colors may seem muted, or your lines might appear fuzzy. If the ink is too runny the colors may bleed into one another or appear closely faded. When ink is on target, printers can create beautiful prints that mimic the picture they're trying to make.

Advantages of Managing the Viscosity in Ink for Flexo Printers

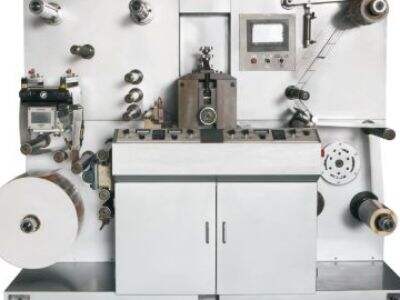

Printers paper cutting machinery find it very useful to keep the ink film thickness in control. It saves them money by using the correct amount of ink for every job. It also saves time because they’re not constantly needing to stop and change etching ink. Most of all, it helps people make prints that make people say, “Wow, that looks great!” Jingle Blue aims to help every printer of their inks achieve the best possible prints.

In the end, ink viscosity may appear a small detail, but it has a big impact on how good a print can look. If they keep the ink consistent and have the proper tools to verify and adjust it, flexo printers can make beautiful prints that pop. Jingle Blue is ready to respond to printers with the best solution by offering top quality inks and ink viscosity control know-how.