Flexo printing is a speedy method to produce a large quantity of printed objects. Key components enable the printer to operate at high speed. So what makes high-speed flexo printers perform so well?

The Major Components of a High Speed Flexo Printing Press

One critical component is the printing plates. These are the plates with all the words and pictures for the printed material. Another key part is the ink. No ink, no pictures or words on that piece of paper. The press is also really key, because it’s where it all happens. It’s the heart of the machine, making sure everything functions as it should.

How Tech Makes Flexo Printing Possible

High-speed flexo makes good sense. They have fancy technology, so everything goes fast and perfecter. The machines can determine exactly how much ink hits the page to make sure that the colors match up just right. They can also whip the paper through the press, so it gets printed up fast. All of these smart features combine to mean that the Inline Flexo Printing Machine prints well and prints a lot of stuff, quickly.

Flexo Printings at High Speeds and Quality

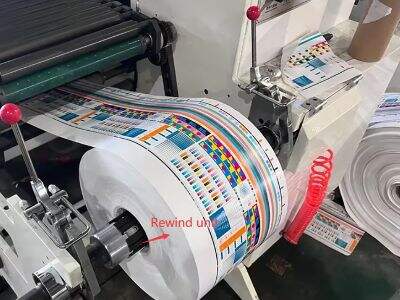

Quality and speed matter in flexo printing. High-speed flexo printers can print very quickly, but they also want to make sure the pictures and words look crisp and inky black. Special tools called color sensors verify the colors are to their exacting standards so everything looks just right. The Flexo Printing Machine also feature specialty rollers that ensure ink is distributed evenly, resulting in smooth and coated finish print.

Better High-Speed Flexo Printers

High-speed flexo printing has had good progress so far in recent years. New technologies have also transformed how these Stack Flexo Printing Machine work, and they’re now faster and better. The big change is the use of digital controls. These controls ensure that your printer adjusts things such as levels of ink and speed of paper immediately, to ensure that everything runs as planned. With these improvements, high-speed flexo presses are now capable of producing very high-quality print at very high speeds.

Maintaining the Good Condition of Flexo Printers

Maintaining a high-speed flexo press is a lot like keeping anything nice: you need to take care of it. It is essential to maintain it on a regular basis to ensure that all the components are functioning properly.” It even involves the process of cleaning the p ress, of examining the ink tanks, and replacing the work out parts. You should also use good materials, like Jingle blue ink, to get the best effect. Smart about the printer, the equipment, the supplies, and speed and accuracy can be maintained in flexo printing.