3) The tension controlling is very important for flexo printing machines. It is useful for maintaining a proper tension on the materials being printed on. This is important in achieving good prints. So in this post we will see why tension control in flexo printing is so important and how it can improve your printing.

The Importance Of Tension Control In Flexo Printing

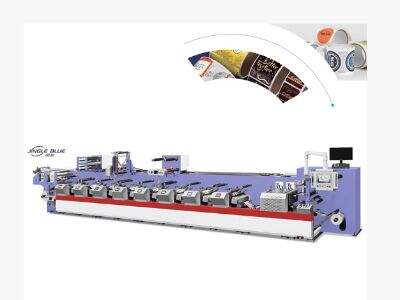

Flexo Printing Machine is a popular means for printing on various materials, such as labels, packaging and newspapers. Tension control is also a requirement for flexo printing as it keeps the materials in place. If the tension isn’t there, it could lead to issues such as wrinkles, stretching or print misalignment.

Achieving Good Print Quality with Good Tension Control

One major advantage of having the correct tension is, it leads to the high quality and the consistency in the prints. And when the tension remains consistent during printing, the prints are clear and crisp. This allows to verify that the end product is of good quality.

The Impact of Tension Control on Print Registration and Color Consistency

Since the printing method use is tensile-based, quality print alignment and color matching are also the result of good tension control. By print alignment, I mean how good different colors and parts of the print line up. When the tension is not correct, this can result in misalignment of the print and poor print quality. Color consistency is also critical in ensuring that the colors match what should be seen. Nice tension control will keep your colors consistent during the process of printing.

Making Printing Easier And More Efficient – Somewhat Greenerentious['<{0xc6be} -="" if="">

Disclosed

Good tension control can speed up the printing process and save materials. When the tension is constant, fewer mistakes are made and there’s less need to reprint — saving time and resources. Additionally, the proper tension control helps reduce waste by ensuring that materials are used efficiently.

Mastering Tension For Improved Flexo Printing

Learning how to manage that tension is best done through an understanding of the printing process and the equipment that is used. So you will want to adjust the tensions along-side of them based on what you are printing and what your material needs to print. One should verify with periodic checks the correct functioning of the tension control system.