The jingle blue stack Flexo printing machine is an amazing piece of equipment, which allows people to print items such as newspapers, magazines and packages. It is a large machine, with many parts that operate together to ensure that printing happens quickly and accurately. In this writing, we are going to features to bring you in the world of stack type Flexo printing machine and why it is just so significant.

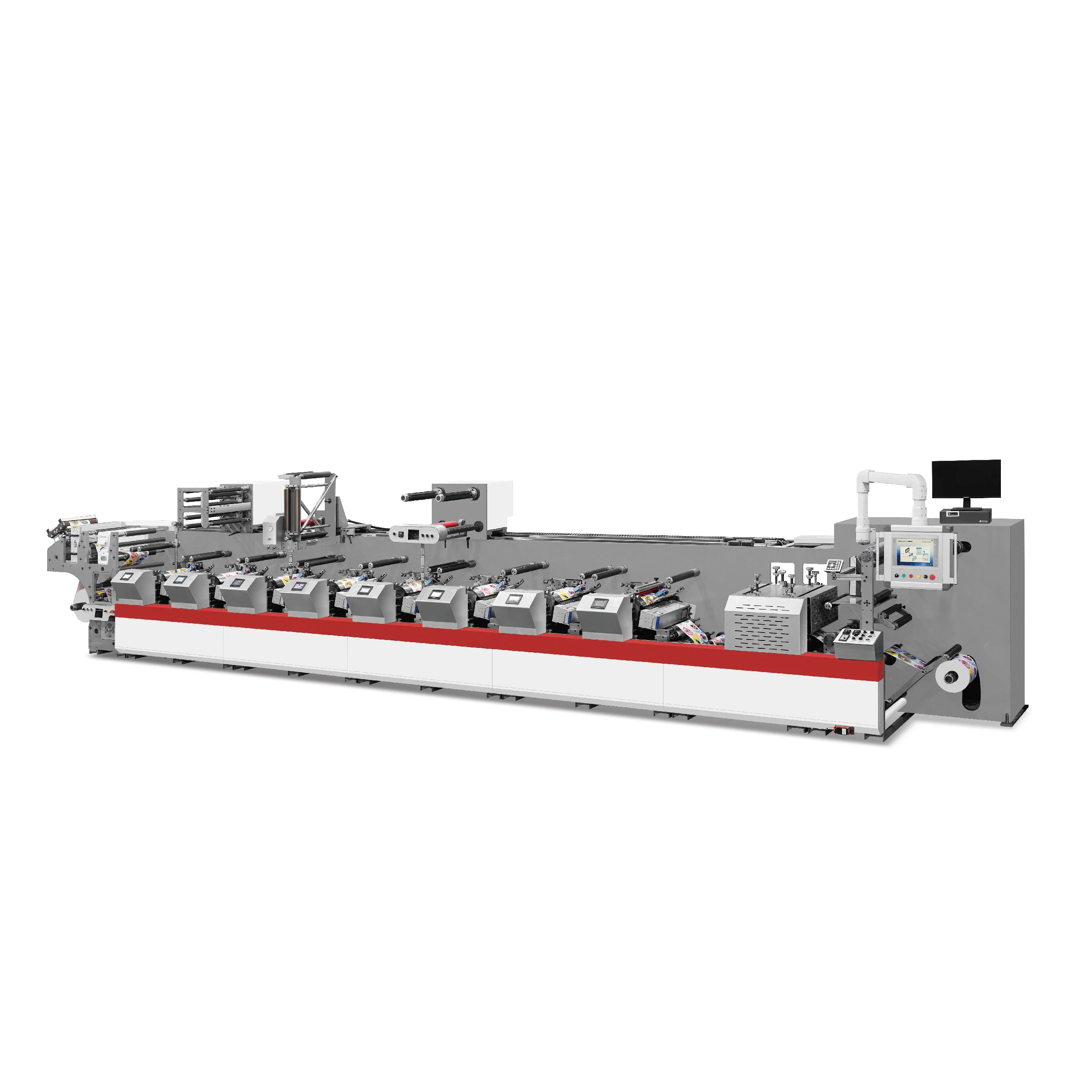

What is a stack Flexo printing machine? Unlike older printers, stack Flexo machines can print on a variety of surfaces, including plastic, metal and fabric. They are very handy for various print jobs. The machine is known as a “stack” machine because it includes multiple printing units stacked on top of one another, making it possible to print many colors at the same time.

The jingle blue Flexo printing machine are plenty of reasons to produce the stack Flexo printing machine. They can print a lot of stuff very quickly. That’s really good for printing newspapers and magazines and things like that that need to be fabricated in large quantities. Another reason is, stack Flexo printing machines print good, clear pictures and nice bright colors. They are dependable too and require hardly any maintenance.

Jingle blue Stack 8 color Flexo printing machine presses changed the printing world in several significant ways. They make it possible for printing to be faster, therefore more efficient, than ever before, so much so that companies can create far more materials in far less time. That has driven down costs and made printing more affordable for businesses of every size. Plus, these machines can print on an array of materials, providing opportunities for some pretty cool projects.

Regular maintenance and cleaning to enlisted the stack 4 colour Flexo printing machine is critical to keep it run smoothly. That entails changing worn out parts, cleaning ink rollers and oiling the machine. It’s not a bad idea to store the machine in a nice clean dry spot to prevent dust from getting inside. With these helpful tips, you can also help your stack Flexo printing machine remain in the very best condition for a number of years.

There are also many new developments in stack four colour Flexo printing machine. These high-quality prints are ready in a bit less time, and feature improved color matching and accuracy. Some machines even feature digital controls that aid with precise printing and color matching. In addition, new materials and inks have been developed to extend printing to wider range of surfaces offering new opportunities in printing. With the advancement of technology we can expect even better progress in stack Flexo printing machines.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog