Paper products undergo several stages of production, including slitting and rewinding. These are steps that assist in cutting large rolls of paper in small and rewinding them tidy. This is done at Jingle Blue using high-tech equipment, and this is why we always have a top-notch product.

The paper products manufacturing process compiles many steps to accomplishing the final product, one of which is slitting and rewinding. This process takes larger rolls of paper, cuts them into smaller sections, and winds them in an orderly manner. You want to ensure the paper is the proper size for items like books, notebooks, or wrapping paper. Without slitting and rewinding, getting the paper we need for everyday items would be a challenge.

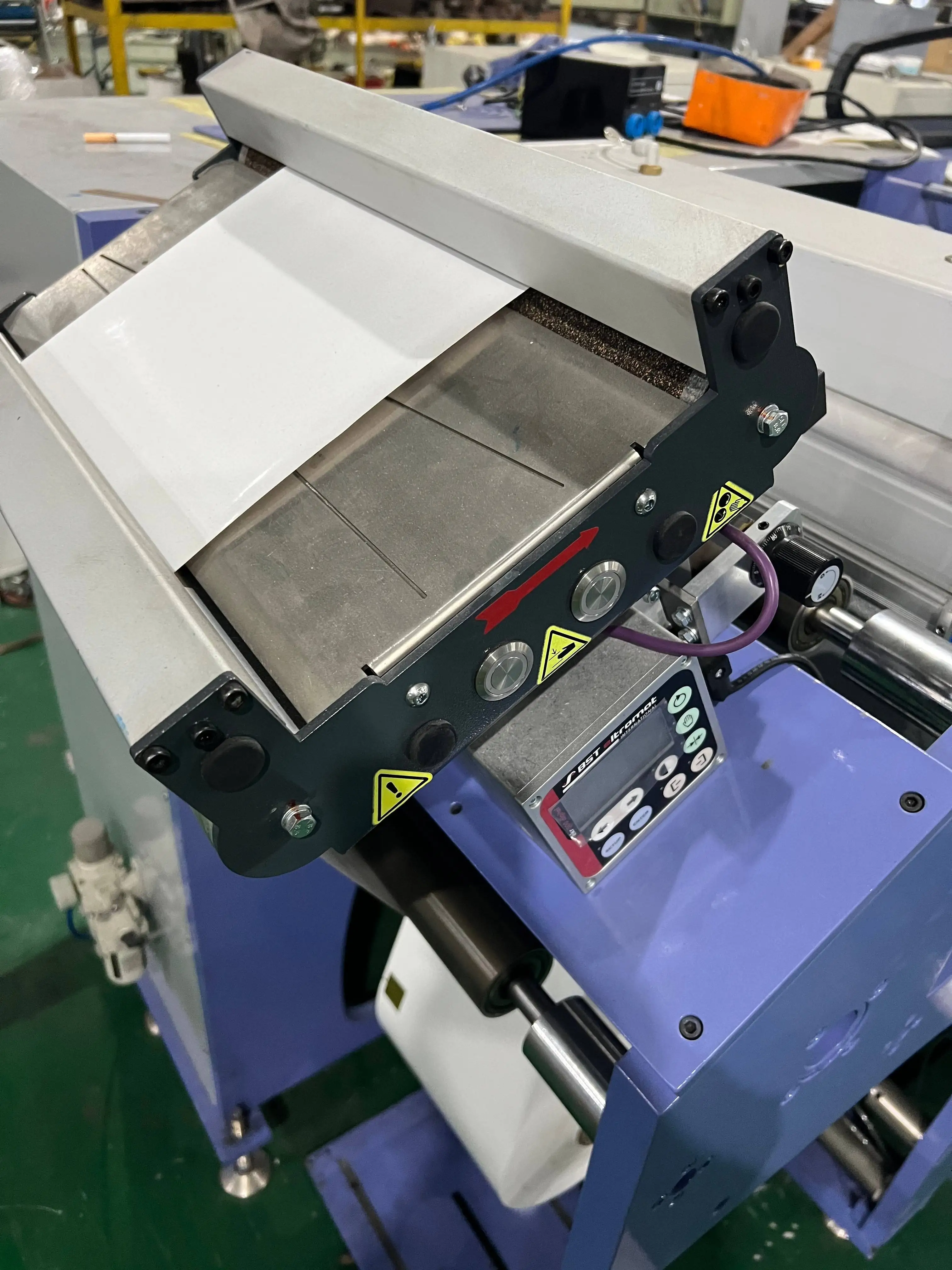

︱OPPPET Re-winder Re-slitter of plastics and OPP, PET Peak.Mock for Rewinders for re-slip and rewinder.

The right equipment and processes is key to successful slitting and rewinding. We have state of the art machinery at Jingle Blue which cuts and winds paper quickly and accurately. We also provide our workers with enough training to be aware of the right usage of machines. When working with the right machines and methods serwetki producent make certain that our paper goods are made precisely every single time.

This is a major factor behind how we make better paper products for our customers. These techniques allow us to cut and wind the paper such that it is tough and durable. It's especially critical for items like books and notebooks. To provide better results, we needed to make sure customers have a positive experience with Jingle Blue.

This can save you a lot of time and money, as these slitting and rewinding machines are extremely helpful and can produce a wide variety of paper products. They can cut and wind paper of various sizes and thicknesses, so they fit a lot of applications. Everything we make includes everything from small notebooks to large rolls of wrapping paper at Jingle Blue. This allows us to serve our customers better.

Optimizing our slitting and rewinding processes, to act faster and waste less. This allows us to produce more paper products in less time and with less resources. With smart use of our machines and not wasting paper, we can make our planet a better place and also save some bucks. Here at Jingle Blue, we are always on the lookout for ways to upgrade our processes and create a more eco-friendly workspace.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog