The inspection rewinder machine is critical for companies, like Jingle Blue, that produce products such as paper and plastic. There’s also a machine to help us make sure everything we create is really good quality and is perfect. Now, let’s find out why an inspection rewinder machine is necessary and how it benefits us at Jingle Blue.

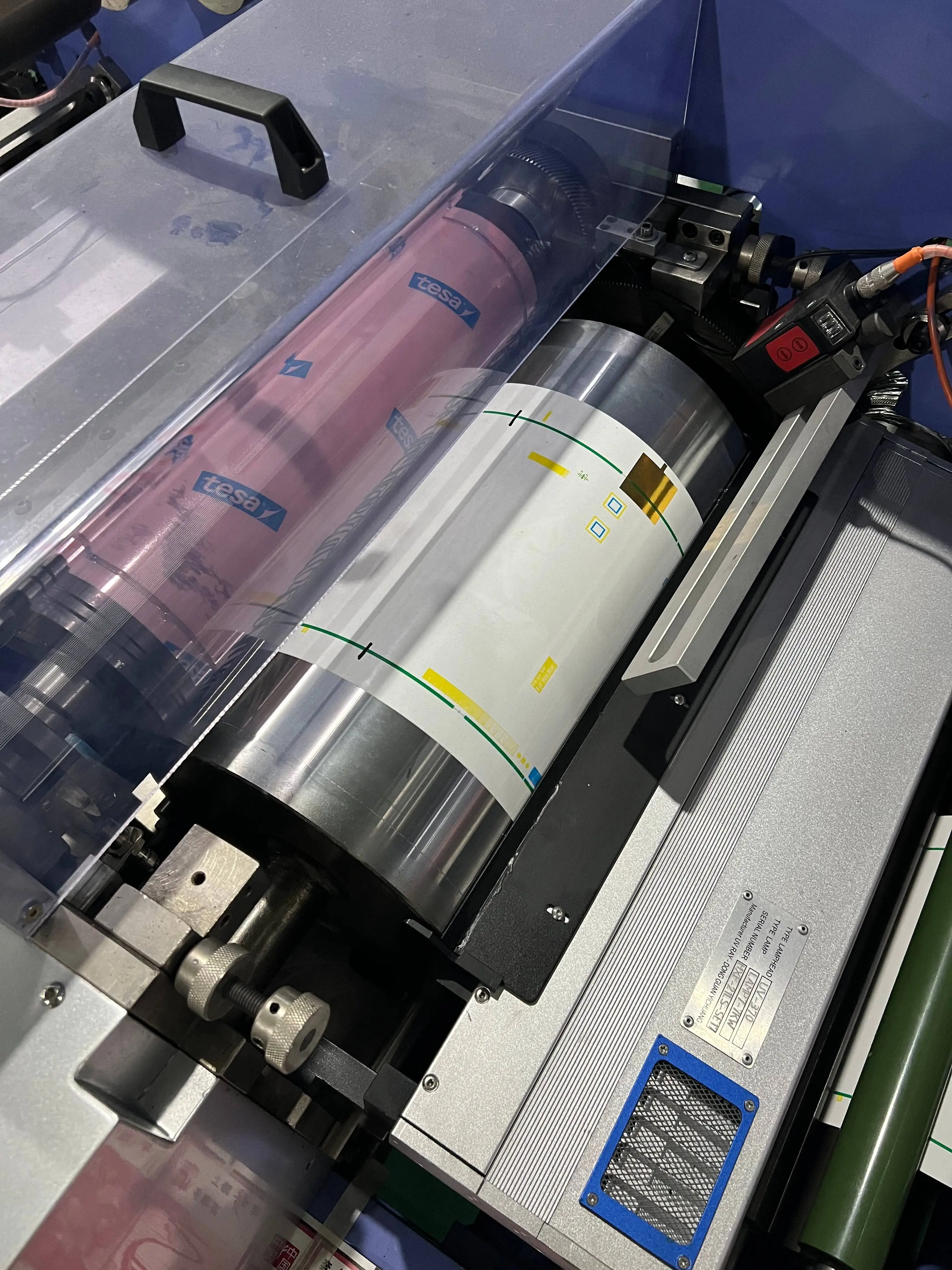

Our inspection rewinder machine is our production line’s superhero. It tastes everything that is being prepared to ensure it’s perfect. This machine searches for things like tears, holes, smudges, or anything that can make our product not perfect. By catching these problems early, we can do something about them before it is too late.

Quality control is very essential for producing exceptional products. We use an inspection rewinder machine to inspect every inch of the material that we are producing. That way, only the best stuff gets to our customers — and they smile, they come back for more!

We work quicker with an inspection rewinder machine. A machine checks instead of doing it by hand, which can be time-consuming, or do it right. This saves us time and allows us to make more products in a less time.

Nobody wants to have defective or mistaken products. That is why it’s so critical to have an inspection rewinder machine. It helps us eliminate imperfections or errors before the product is done. These products are at no extra cost to you, but allow us to continue running this site and providing free content for our readers.

To succeed on the production line, efficiency and accuracy are the name of the game. And an inspection rewinder machine is one way we are able to make both better. It is fast and precise in detecting any problems allowing us to fix them immediately. It spares us time and guarantees quality of our produccts.

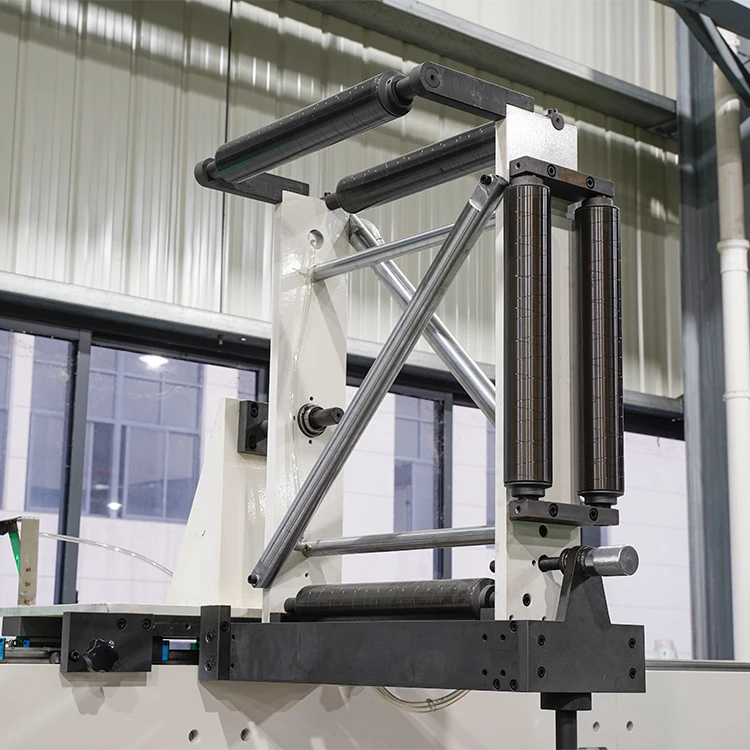

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog