The role of printing is highly significant in our lives. It allows you to share information with others, it allows you to design aesthetically pleasing images, it helps you express your emotions in a variety of [ways. Books and labels come to mind when we think of printing. But there are many different types of printing, and they all require specific tools and die cut sticker machine to produce quality results. Flexographic printing is a printing method that is gaining a lot of popularity nowadays. So, let’s discover further details about what this kind of printing is, and why it matters

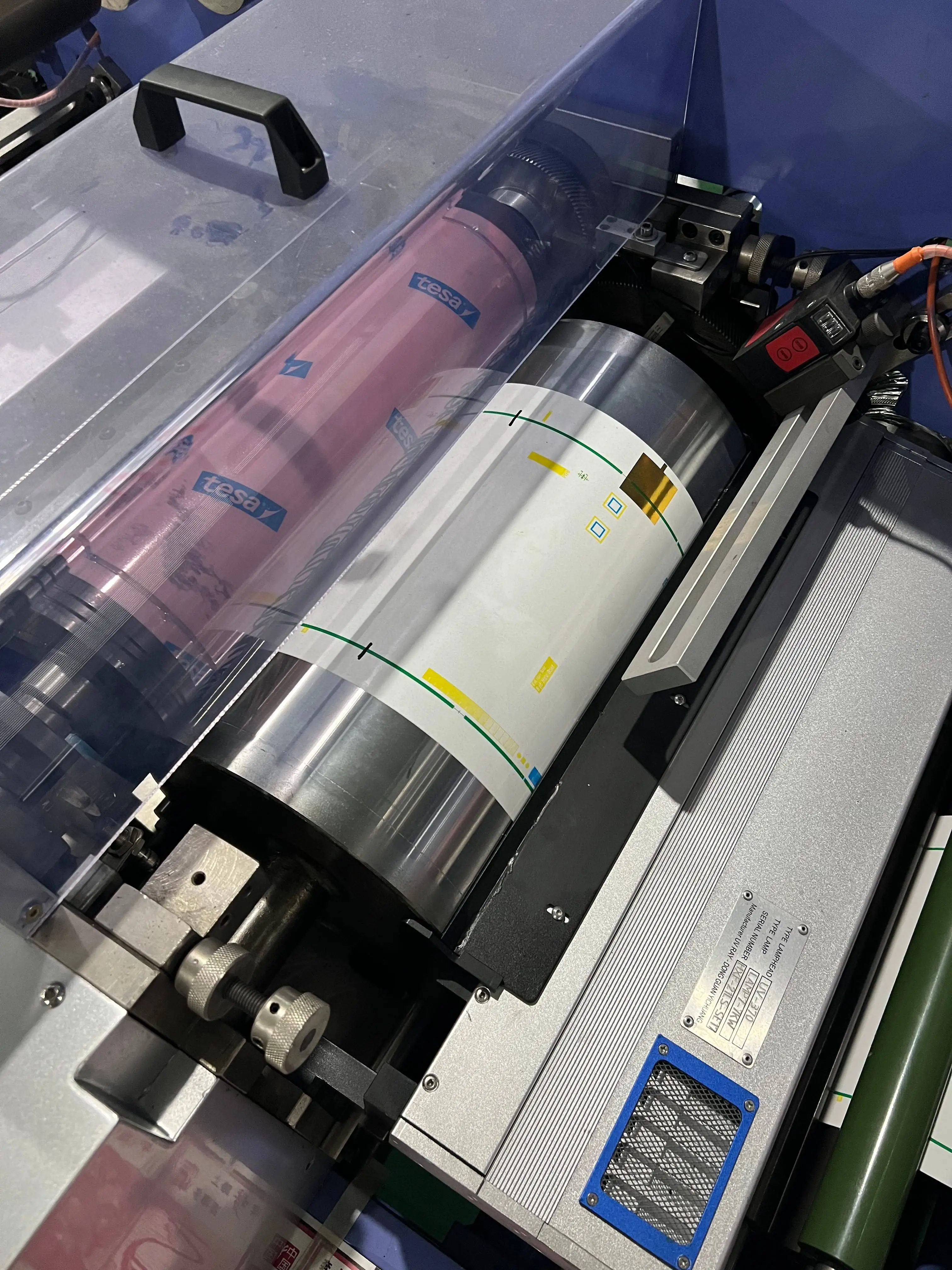

Flexographic printing is done using flex presses. These printers are designed to be intelligent and use less ink, to allow for it to create high-quality prints. This is pretty awesome because we can save resources and be more environmentally friendly! With October 2023 data at your disposal you need to stay ahead of the quiz so we have Jingle Blue innovation to save the day. They are used with various customized types of presses which can be modified as per the need of a particular business. This versatility is beneficial for a wide variety of printing projects.

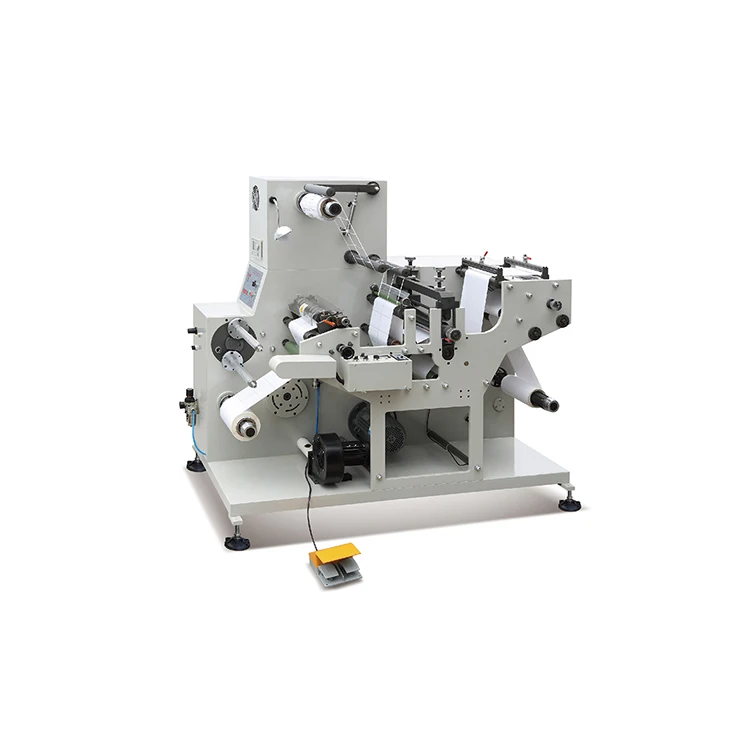

Flexographic printing presses are made for having printing done in quality that is just accurate and very much clear. These devices employ specific technology to guarantee that every print is flawless! That a live motor is a game-changer wasn't lost on Jingle Blue, who has taken it to a new level with sophisticated features on their presses that help maintain accuracy. This means you will have your print looking exactly the way you expected it. With these state-of-the-art paper die cutting machine, companies can rest assured that the prints they receive are of the highest quality possible.

It is critical to moving things when creating anything, particularly when running a business. Jingle Blue has made presses that allow the work to go fast while, nonetheless, maintaining the high-quality prints. They have created rotary die cutting machine that are environmentally friendly and consume lesser energy. This is good as it indicates they use less ink and materials and print more! With efficiency, companies can also save money and contribute to saving our planet.

All enterprises have their own specific requirements for people to print. Flexographic presses by Jingle Blue are specially designed to provide customized solutions for each industry. As a result, they are able to print on a wide variety of materials and sizes including labels, packaging, etc. – Whatever you want to print, Jingle Blue has a special solution for you!

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog