The function of flexo printing and die cutting machines is an indispensable equipment in the packaging field. These machines enable companies to produce colorful, eye-catching packaging for their products. In this post, we will take a look at the advantages offered by Flexo Printing Machine and die cutting machines. We’ll explore how they can enable companies to work better and faster, what they can do and how they enhance the design of packages. We will also learn how these machines are making it easier for companies, like Jingle Blue, to produce.

Flexo printing and die cutting equipments have numerous advantages for businesses. An advantage of this is that they can produce quality prints extremely quickly. This helps firms that must meet tight deadlines and deliver products on time, to customers. And, these machines are money savers, and that is one of the reasons why many businesses consider the use of this machine when packaging. Flexo printing and Die Cutting Machine are also versatile enough to allow companies to design special shapes and designs for their packaging, ensuring they stand out on store shelves.

Opting for flexo printing and die cutting technology ensures the companies are able to work better and faster. These machines, of course, can process a lot of printing and cutting at one go, and it has saved a lot of time and effort in package production. Faster turnaround means that businesses can satisfy customer needs, quickly, and gain a competitive edge. A good example is Jingle Blue, a company that has raced ahead since it began to use the flexo printing machine and die cutting machine. This allows them to fulfill orders more quickly and efficiently.

Flexo printing and die cutting machines are capable of doing a lot of stuff, which is why it’s a handy piece of equipment for making packaging. These machines work on various materials such as paper, card board and plastic. That enables companies to design packaging for a wide variety of products. And, the process of flexo printing and die cutting machines can be featured with precision, detailed designs and shape cuts. This allows companies an opportunity to get creative with their packaging. Cooling Blue has leveraged these features to develop eye-catching packaging designs that draw in new customers and drive sales.

Flexo printing and die cutting machines enable companies to enhance the style of their packaging and have their product stand out. These devices are capable of printing vivid colors and sharp images, and have products looking more attractive to the consumers. Companies may also incorporate special shapes and designs for their packaging with die cutting technology. This sets them apart from their competition. Jingle Blue, for instance, has employed high-speed flexo printing and die-cutting machines to produce packages that demonstrate its brand and have an appeal to its customers, attracting more brand familiarity and loyalty.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

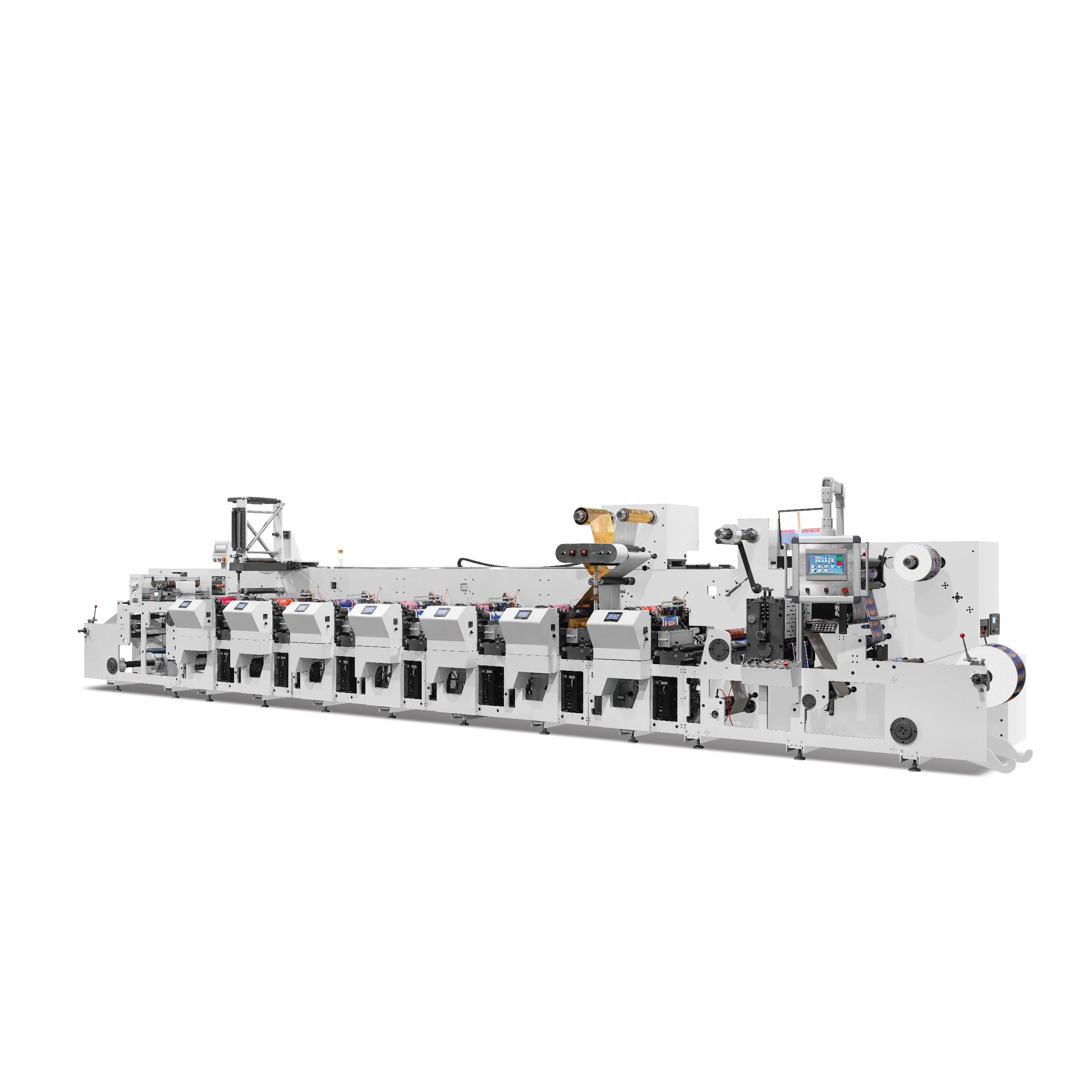

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog