Slitting and cutting machines are widely used in the factories. They ensure things are fast and right. These machines, after all, can cut through such materials as paper, plastic, metal and even fabric quite well. These machines are produced by a company called Jingle Blue, and they’re used in a wide variety of industries.

One of the ways cutting and slitting machines can be beneficial is in that they ensure that things are cut the exact same way each time. For instance, if you want to cut a piece of paper into 10 equal parts, a cutting machine is capable of doing this with exact precision. This helps to ensure they’re all the same size and shape.

And it turns out these machines have another great quality: they save money and work more quickly. They can cut things much faster than a person could by hand. This is also time and cost saving for companies that can produce more material in less time. It also can work to keep costs down, which is good for businesses and consumers alike.

Cutting/slicing machines are utilized by various sectors. These machines are used, say, in the packaging industry, to cut up paper and plastic for forming boxes. The textile industry uses them to slash fabric for clothing. Automakers use cutting machines to carve metal parts for cars. These machines have a plethora of uses.

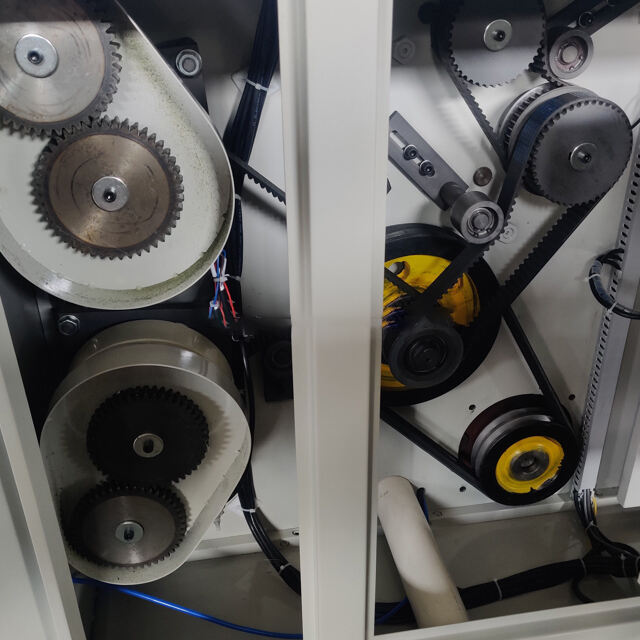

Cutting and Slitting Machines have specialized technology for working better. Some machines have sensors where the sensor for the size that you are cutting will be activated to show you the exact size needed for cutting. This ensures that the finished products are of a high quality and adhere to industrial standards. This equipment also helps to lower the error rates when in production.

One critical upside to these machines is that they help reduce waste. They can saw through materials with minimal waste. It saves scarce resources and is good for the environment. Not only that, companies can produce less scrap material with these machines, saving money and lowering waste.

The company boasts a professional team skilled in printing, design, manufacturing, and maintenance. By integrating advanced technologies from both domestic and international markets, they continuously enhance product quality and performance.

With a well-established quality management system and standardized safety production practices, the company ensures all equipment meets high industry standards and provides safe, reliable solutions.

Committed to innovation, the company has developed energy-efficient products like the fully automatic high-speed flexographic printing press and full-servo die-cutting machine, offering high output with low energy consumption.

The company produces a wide range of high-quality printing machines, including flexible letterpress, full-rotation printing machines, roll-to-roll screen printing machines, and self-adhesive die-cutting machines, catering to various market demands.

Copyright © Zhejiang Jingle Blue Printing Machinery Co., Ltd All Rights Reserved - Privacy Policy - Blog